Handling poultry isn’t easy

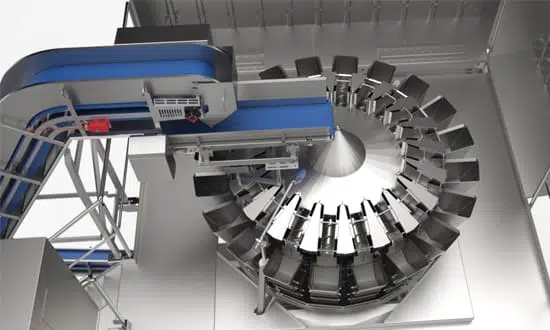

Our processing equipment is the perfect tool to handling meat and poultry! With our meat- and poultry weigher everything gets easier.

Achieving high yields from fresh and sticky products, like marinated meat and poultry, poses a particularly tough processing challenge. Fortunately, we love challenges!

The trend towards packing of fresh and frozen meat to fixed weight continues. Supermarket chains are focusing on reduced waste and optimized inventory control, and fixed weight trays contribute considerably to this. As a result, the meat and chicken processing industry needs to look for ways to reduce give-away, cut costs, and increase efficiency in order to remain competitive.

Our customized weighing, filling and packing solutions provide accurate portion weighing, which results in increased capacity, reduced giveaway, and significantly increased yields.

Minimal giveaway with the patented Screw-Feeding Multihead Weigher

Automated systems that reduce labor costs and increase overall efficiency

Fixed weighing and portioning systems that ensure uniformity and meet industry standards

Selected complete processing solutions to improve your production

Advanced Technical Expertise

Some of our key weighing solutions include:

Cabinplant SensorFeed®: This innovative feeding system ensures accurate, continuous feeding of products to weighing and packaging lines, optimizing efficiency.

Poultry processing

Increased automation

Targeted solutions

Cabinplant provides tailor-made solutions for multihead weighing and packing of poultry products, such as:

Fresh or IQF deboned poultry products, including fillets, stripped/diced and marinated products

Fresh or IQF bone-in poultry products, including drumstics, leg quarters, wings etc.

Fresh and sticky by-products such as giblets, chicken feet and heads

Processed poultry products including nuggets, hot wings etc.

Fixed Weighing and Portioning

Cabinplant’s expertise and technical know-how extends beyond basic processing to include specialized solutions for fixed weighing, portioning, and overall processing efficiency:

Our fixed weighing systems ensure consistent and precise weights for poultry products, crucial for meeting standards and ensuring uniformity. The integration of advanced sensors and control systems provide real-time adjustments, maintaining accuracy across the processing line. Our portioning solutions help meet customer specifications while maximizing yield and improving product quality.

References

We have grown together. They have helped to develop our production processes further, particularly within weighing and packing, enabling us to deliver ever-more sophisticated chicken products to the retail sector...

What is poultry processing?

At Cabinplant processing in poultry we focus on the last step of the value chain aiding in the weighing, portioning and packing process.

How can our solution help your production?

Our equipment helps effectivize your production plant increasing speed and reliability while minimizing giveaway

What sets Cabinplant's poultry processing equipment apart from other solutions on the market?

Cabinplant’s solutions are designed to enhance production efficiency by providing accurate and continuous product feed, precise portion control, and optimized product yield and giveaway

How can you ensure smooth integration of your products with our production line?

Cabinplant provides comprehensive support and services to ensure smooth integration and operation of our equipment. This includes consultation, customized design, installation, and ongoing technical support.

Are Cabinplant’s weighing and portioning systems adaptable to different types of poultry products?

Yes, Cabinplant’s weighing and portioning systems are highly adaptable to various types of poultry products, including fresh, marinated, and IQF products. Our fixed weighing systems provide consistent and precise weights for all types of poultry, ensuring product uniformity. The equipment is designed for real-time adjustments to maintain accuracy and meet customer specifications for different portion sizes.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.