Tasty convenience food made easy from a-z with simple convenience food systems

Ready food: Ready, set, serve. Convenience foods are becoming an indispensable part of modern food. With more money to spend and less time to cook, consumers are prepared to buy ready-meal solutions or pre cooked/processed foods to save time. At the same time, they are looking for quality in raw material and taste, and the demands for the convenience food manufacturers are therefore continuously increasing.

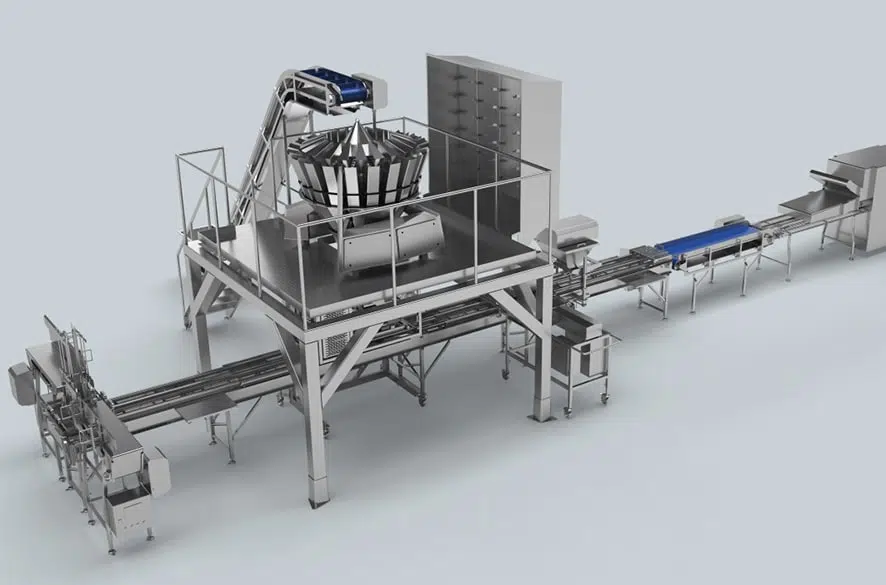

We provide tailor-made solutions for the convenience foods industry that meet the needs of modern consumers and optimize yield, throughput, and product quality.

Are you producing convenience food and would like to learn more about our convenience food systems?

If you want to talk with one of our employees about a tailored convenience food solution, you are more than welcome to contact your local agent.

References

Other benefits

- Higher food safety due to minimized risk of cross-contamination

- Decrease in recruitment costs

- Save production space

- Downtime only 30 min pr product turnover

Send the result

Your results have been sent

Calculated as an average

Size of the spring roll sheets? -; 145 millimeters

Selected complete processing solutions to improve your production

Cabinplant has backed us up all the way through our project; from the preliminary tests in Denmark up until the final running-in of the line after industrial trials on site. The teams have proved receptive to our demands and were able to meet our requirements. During the start-up phase, Cabinplant has supported us on site and by remote service to obtain our goals.

Benefit from 50+ years of experience

Our solutions are developed by combining our weighing technology experience with our 50+ years of experience within other areas of the food industry. We tailor-make solutions to match individual requirements, and we provide complete solutions for weighing, filling and packing products into bags, buckets, cans, glass jars, cups and trays; premade, thermoformed etc.

Contact a specialist