Poultry processing equipment that makes handling easier

Poultry processing equipment makes handling meat and poultry simpler, faster and far more precise. Our systems are designed to process both fresh and marinated products with care, ensuring consistent quality and high efficiency throughout the entire production line.

Working with fresh or sticky products such as marinated meat and poultry often challenges even the most advanced processors. As trusted poultry equipment manufacturers, we understand these demands and create reliable technology that delivers high yields, accuracy and hygiene.

The growing demand for fixed weight packaging of fresh and frozen poultry pushes the industry to focus on waste reduction and optimized inventory control. To stay competitive, processors need efficient ways to minimize giveaway, lower costs and increase output.

Our poultry processing solutions combine precise weighing, filling and packing systems that help you reach those goals. With customized designs and advanced controls, you gain higher capacity, reduced giveaway and significantly improved yields — every single day.

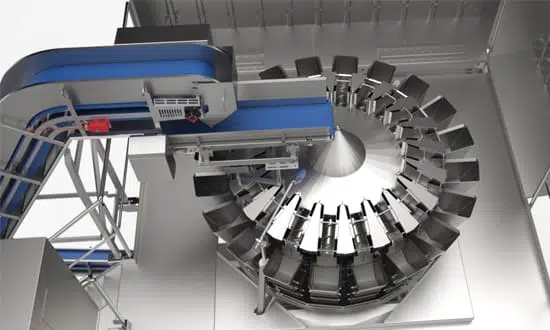

Minimal giveaway with the patented screw-feeding multihead weigher

Automated systems that reduce labor costs and increase overall efficiency

Fixed weighing and portioning systems that ensure uniformity and meet industry standards

Weighing of poultry is our speciality

Poultry processing equipment plays a vital role in achieving accurate and efficient weighing throughout production. Our systems are designed to handle everything from small cuts to whole birds with minimal giveaway, ensuring consistent weight, quality and throughput.

As leading poultry equipment manufacturers, we specialize in developing weighing technology that delivers outstanding precision and reliability. Accurate weighing is the foundation of an efficient poultry line, helping you meet retail and foodservice standards while maintaining product integrity.

Our technology ensures fixed weight portions that meet strict retail and foodservice requirements while maintaining speed and product quality. By integrating our advanced poultry processing solutions, you can optimize yield, reduce product loss and achieve full control over every batch.

Whether you are upgrading an existing line or building a new one, our tailored equipment is designed to fit seamlessly into your production flow — helping you achieve more consistent results and a stronger bottom line.

Selection of poultry processing equipment to improve your production

Advanced technical expertise

Some of our key weighing solutions include:

Cabinplant SensorFeed®: This innovative feeding system ensures accurate, continuous feeding of products to weighing and packaging lines, optimizing efficiency.

Poultry processing

Increased automation

Targeted poultry processing solutions

Cabinplant provides tailor-made solutions for multihead weighing and packing of poultry products, such as:

Fresh or IQF deboned poultry products, including fillets, stripped/diced and marinated products

Fresh or IQF bone-in poultry products, including drumstics, leg quarters, wings etc.

Fresh and sticky by-products such as giblets, chicken feet and heads

Processed poultry products including nuggets, hot wings etc.

Fixed weighing and portioning

As experienced poultry equipment manufacturers, we deliver poultry processing equipment that goes far beyond basic functionality. Our advanced weighing and portioning systems are designed to ensure accuracy, consistency and efficiency across your entire production line.

Our fixed weighing systems guarantee precise and uniform weights for every poultry product — a key factor in meeting retail standards and maintaining product quality. Built-in sensors and intelligent control technology enable real-time adjustments, securing the highest level of accuracy even during continuous operation.

With our tailored poultry processing solutions, you can meet customer specifications with confidence while maximizing yield and minimizing waste. The result is a more efficient process, improved product quality and a stronger return on investment.

References

We have grown together. They have helped to develop our production processes further, particularly within weighing and packing, enabling us to deliver ever-more sophisticated chicken products to the retail sector...

What is poultry processing?

At Cabinplant processing in poultry we focus on the last step of the value chain aiding in the weighing, portioning and packing process.

How can our solution help your production?

Our equipment helps effectivize your production plant increasing speed and reliability while minimizing giveaway

What sets Cabinplant's poultry processing equipment apart from other solutions on the market?

Cabinplant’s solutions are designed to enhance production efficiency by providing accurate and continuous product feed, precise portion control, and optimized product yield and giveaway

How can you ensure smooth integration of your products with our production line?

Cabinplant provides comprehensive support and services to ensure smooth integration and operation of our equipment. This includes consultation, customized design, installation, and ongoing technical support.

Are Cabinplant’s weighing and portioning systems adaptable to different types of poultry products?

Yes, Cabinplant’s weighing and portioning systems are highly adaptable to various types of poultry products, including fresh, marinated, and IQF products. Our fixed weighing systems provide consistent and precise weights for all types of poultry, ensuring product uniformity. The equipment is designed for real-time adjustments to maintain accuracy and meet customer specifications for different portion sizes.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.