Preperation Automation

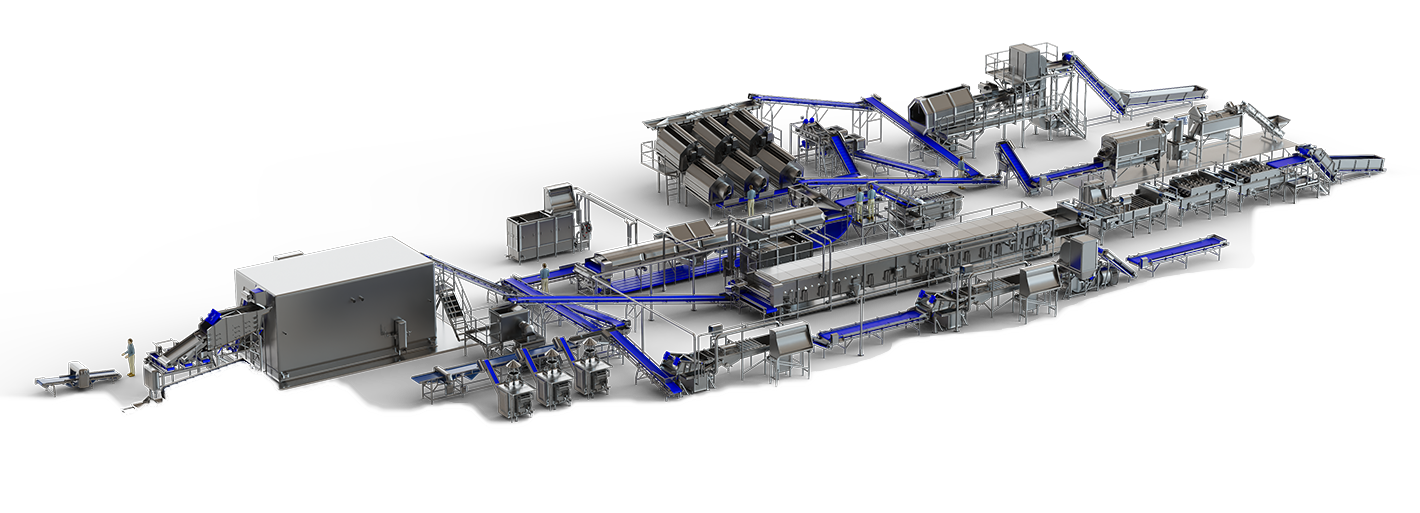

Multi-purpose IQF vegetable line

The Cabinplant Multi-purpose IQF Vegetable Processing Line ensures the maximization of your seasons by harvesting the power of a single solution that can process year-round products. The solution can be customized to fit your needs by strategically coordinating and optimizing your manufacturing process to maximize capabilities.

Download our brochure below to learn more about the various technologies that can be applied in a Cabinplant Multi-purpose IQF Vegetable Processing Line.

"*" indicates required fields

Flexibility and Integrated Recipe Control for the Entire Line

Full Traceability of Product

Reporting System for Process Data and Temperature

Information about our Multi-purpose IQF Vegetable Line

Maximizing Solution

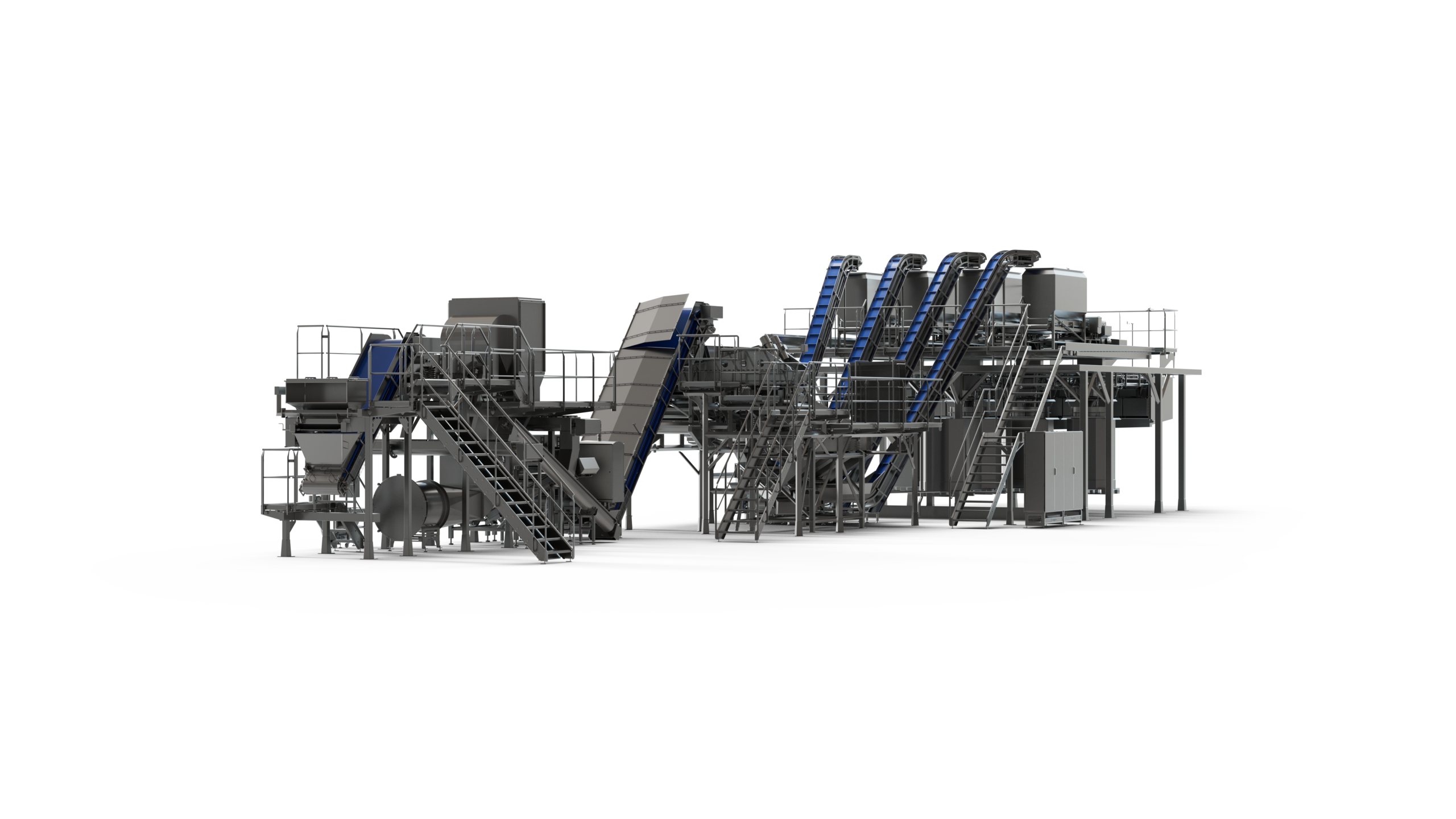

Enhance efficiency with Cabinplant’s innovative multi-product line technology. Our adaptable processing lines manage various tasks, including cleaning, washing, blanching, freezing, sorting, weighing, and packaging vegetables such as peas and beans. Engineered for versatility, they support activities like snipping, cutting, peeling, dicing, and slicing, quickly adjusting to future requirements for crops like maize and leafy greens. A centralized control system ensures seamless operation, while our design focuses on conserving water and energy, adhering to the highest hygiene standards to enhance production efficiency.

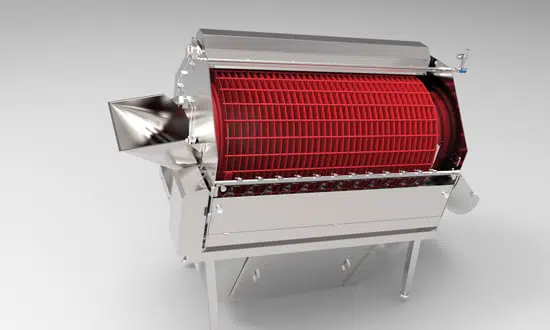

Type of cleaning:

Cleaning and washing vegetables is essential to ensure a high-quality product. The various growing environments influence the amount of cleaning required. Different cleaning systems can be incorporated to guarantee thorough cleaning while optimizing the quality of products and recipes.

- Air cleaning for removal of leaves and light debris

- Root Processing line with drum washer

- Pea Cleaning Line with airflow separator and a washing flume with spray nozzles for thorough cleaning and sand/stone separation

- Flotation wash for the removal of floating foreign matter, as well as dirt and small stones from the product

- A multi-washer designed for floating and sinking products provides quick and efficient washing and rinsing.

- Washing line for Molokhia and spinach with a three-step counterflow water system that significantly minimizes water consumption while ensuring optimal cleanliness.

- A Baudelot water chiller to keep the washing water cold, thereby protecting the berry quality by preventing deterioration due to heat.

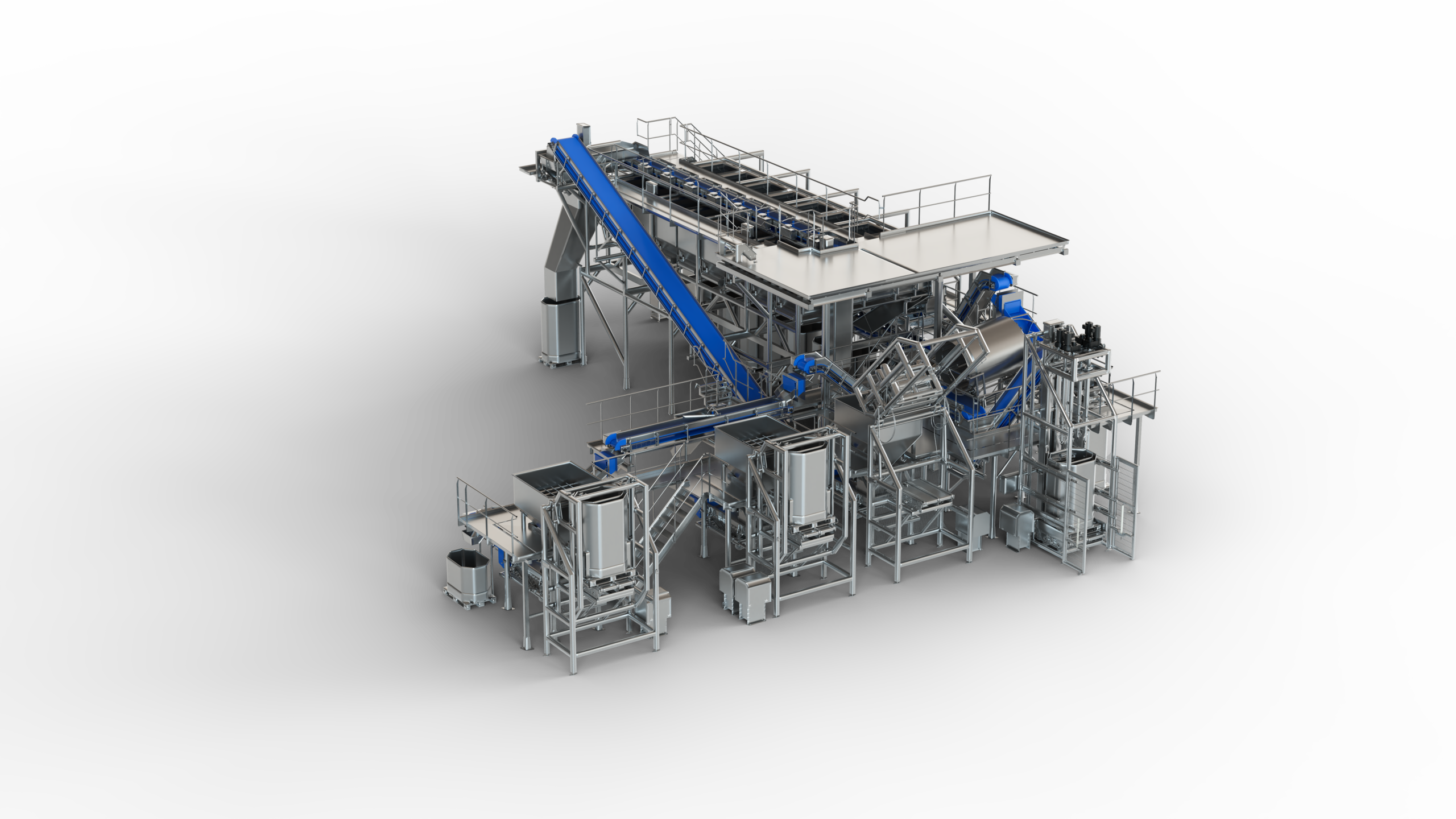

Blanching

Cabinplant has developed various blanchers to enhance product processing and meet diverse needs. The BC Blancher provides a compact solution ideal for limited capacities. The IBC Blancher features 60% reduced energy usage and incorporates advanced steam technology. The BACW Blancher prioritizes water efficiency, establishing itself as the most cost-effective option by utilizing up to 75% less water.

Glazing and packaging line

When temperatures drop below freezing, the product is raised to a vibrating sizing grader, where it is sorted into four distinct grades. Each of these grades is then directed to separate packing stations. If desired, an additional glazing step can be incorporated before packing. The water volume can be adjusted according to the product’s various sizes during the glazing process. This optimization ensures optimal weight gain without requiring the berries to undergo defrosting.

Environmental considerations

Our design optimizes water and energy consumption while maintaining strict hygiene standards. Effective resource management, including the handling of residual products, minimizes waste and maximizes productivity.

Features & benefits

- Gentle Treatment

- Full Traceability

- Line flow control

- Easy recipe handling

- Customizable Solutions

- Efficient workflow

- Flexible/integrated recipe control for the entire line

- Minimum noise level

- Minimum maintenance

- Hygienic design

- Cutting-Edge Technology

- Visualization of performance parameters

- Reporting system for processing data/temperature

- Remote control support

Contact a specialist

We have people all around the world who can help.

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen

Product gallery

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.