Heat treatment

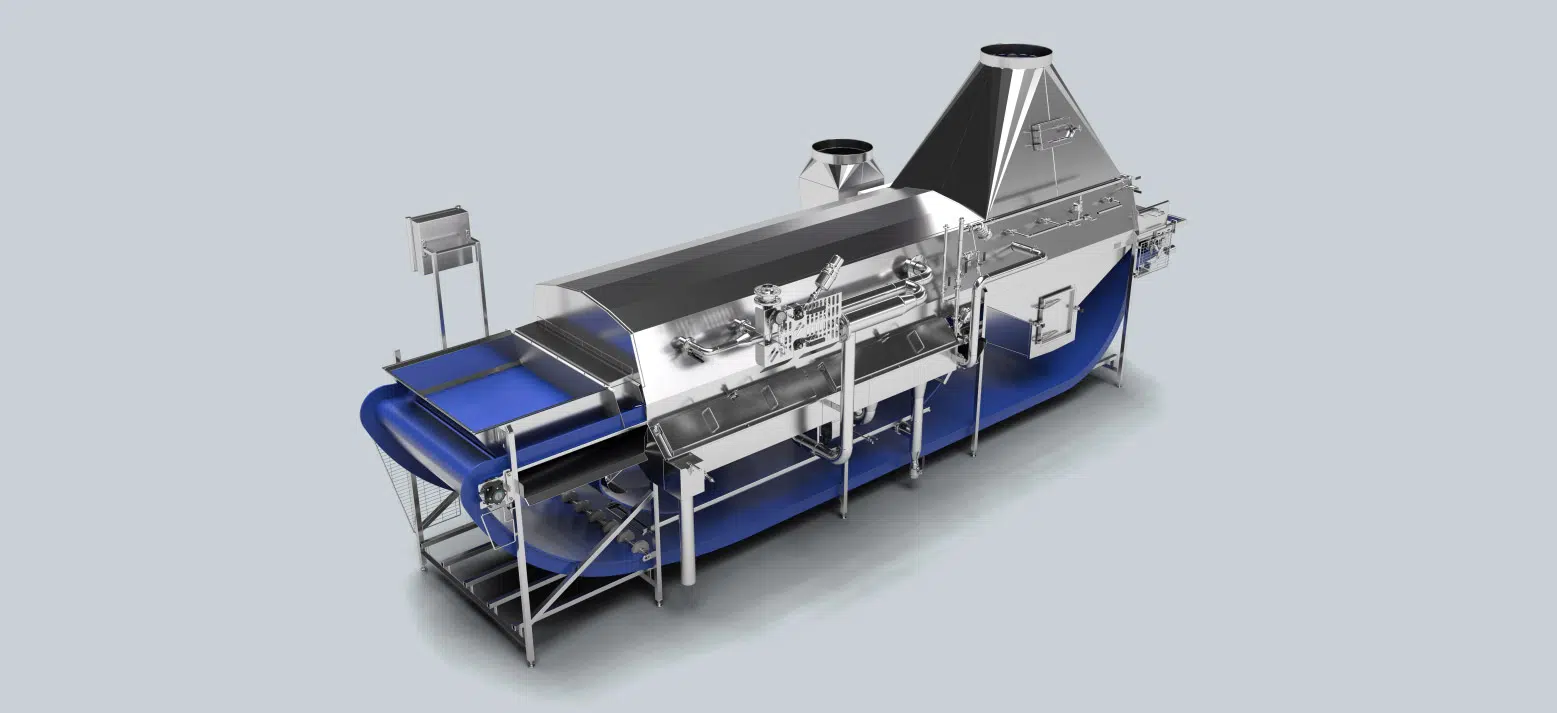

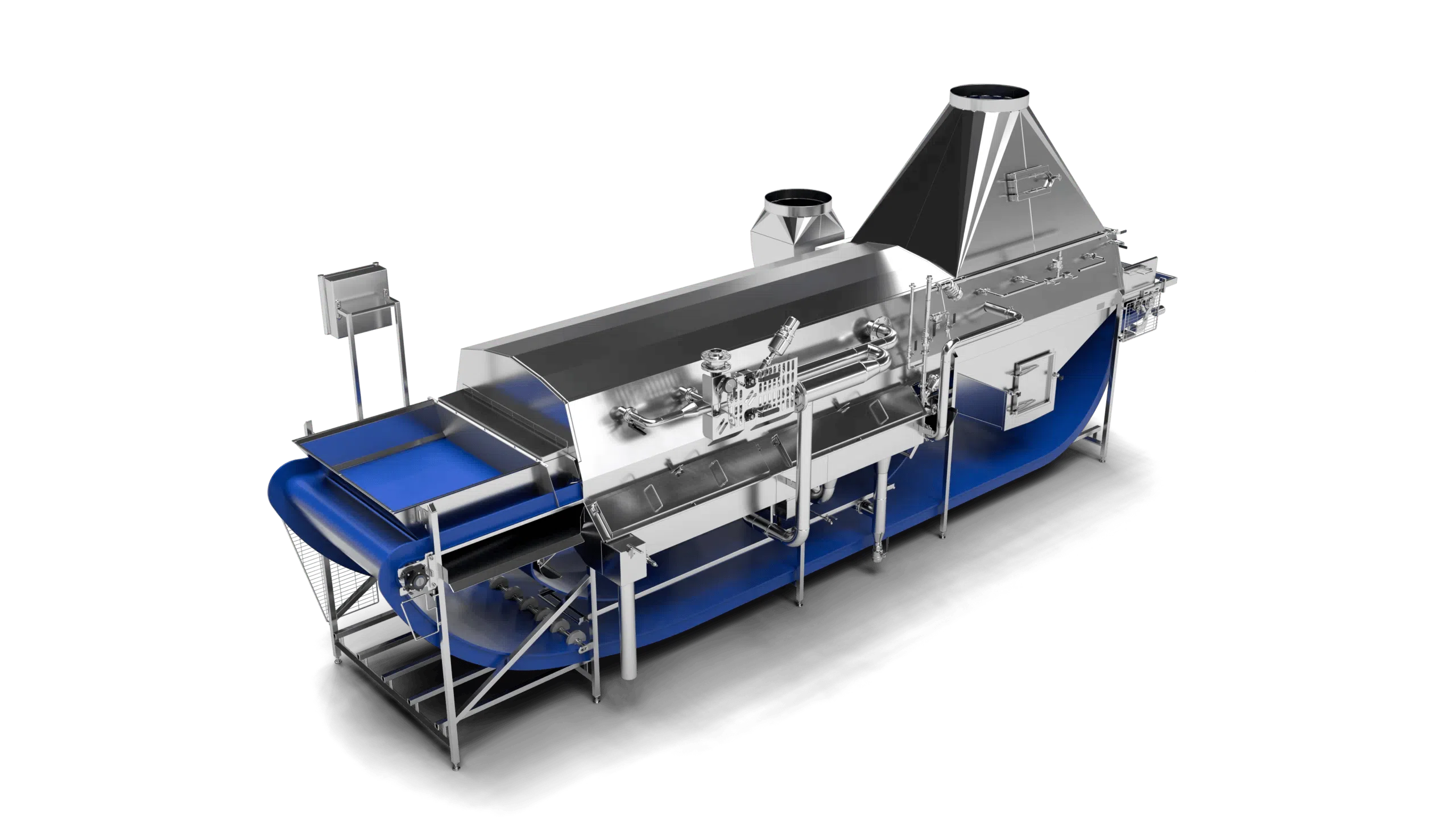

BAC Blancher

The Cabinplant BAC blancher/cooler stands out as the most cost-effective solution for conserving water during the cooling process. This efficiency is achieved through a cooling mechanism driven primarily by evaporation or a combination of evaporation and the utilization of chilled water. The choice between these methods depends on the desired product discharge temperature.

Unlike the IBC, another integrated blancher/cooler system utilizing counterflow water cooling, the BAC employs air as its refrigerant. Consequently, the BAC blancher/cooler remarkably reduces water consumption and nearly eliminates wastewater generation. Compared to conventional blanching systems, the BAC consumes up to 75% less water and generates approximately 60% less wastewater.

Through the use of evaporative air cooling, the BAC blancher/cooler can efficiently lower the product temperature to the range of 20-30˚C, with the exact outcome contingent upon ambient air temperature and humidity levels.

Download our brochure below and learn more about our BAC blancher

"*" indicates required fields

Nearly reduced water waste

No product damage

Low risk of food contamination

Wastewater

The evaporative method necessitates the use of water to prevent product loss and enhance cooling efficiency. In contrast, air cooling minimizes water consumption significantly. However, evaporative cooling does not allow for the recovery of latent thermal energy within the product.

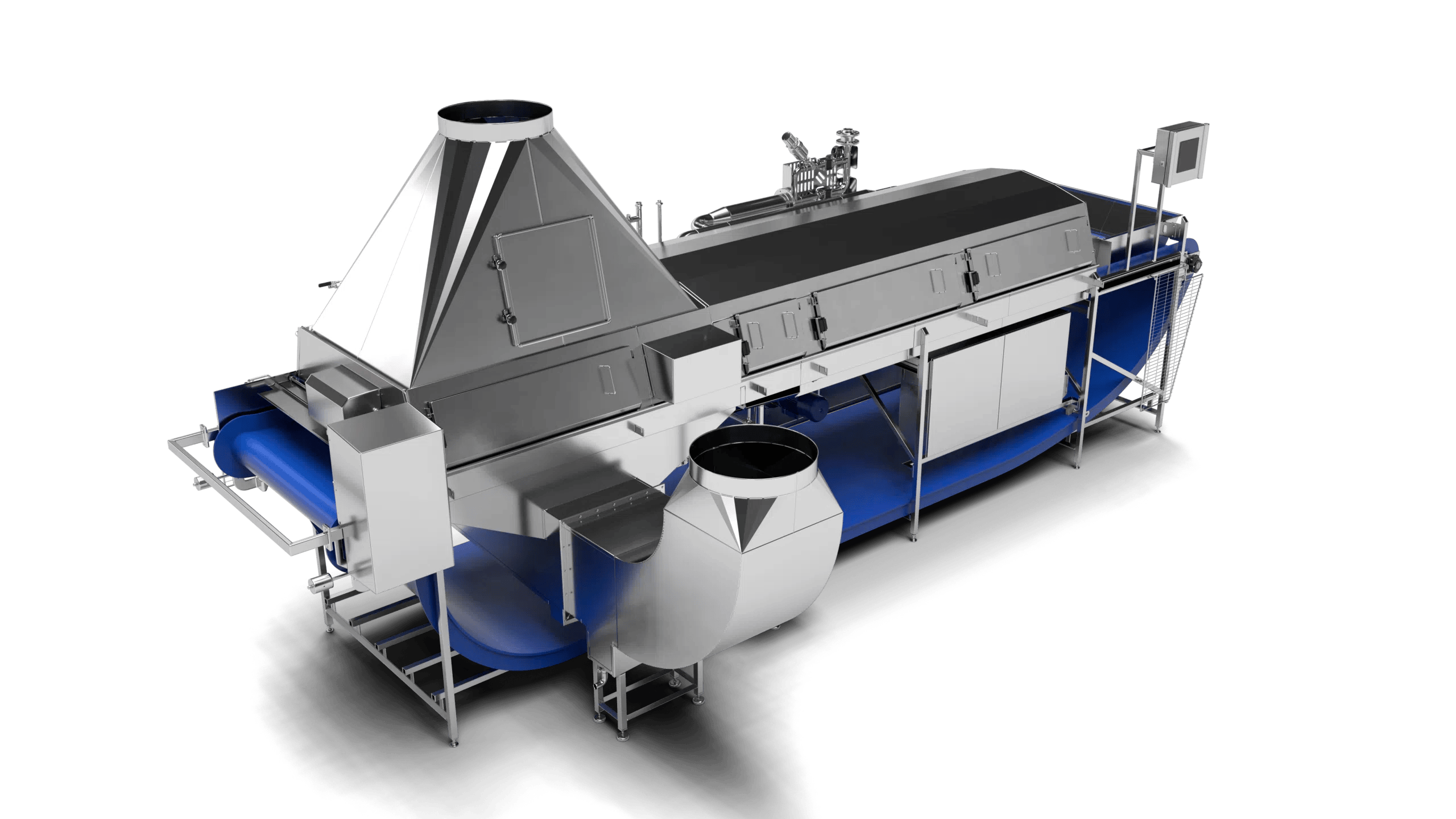

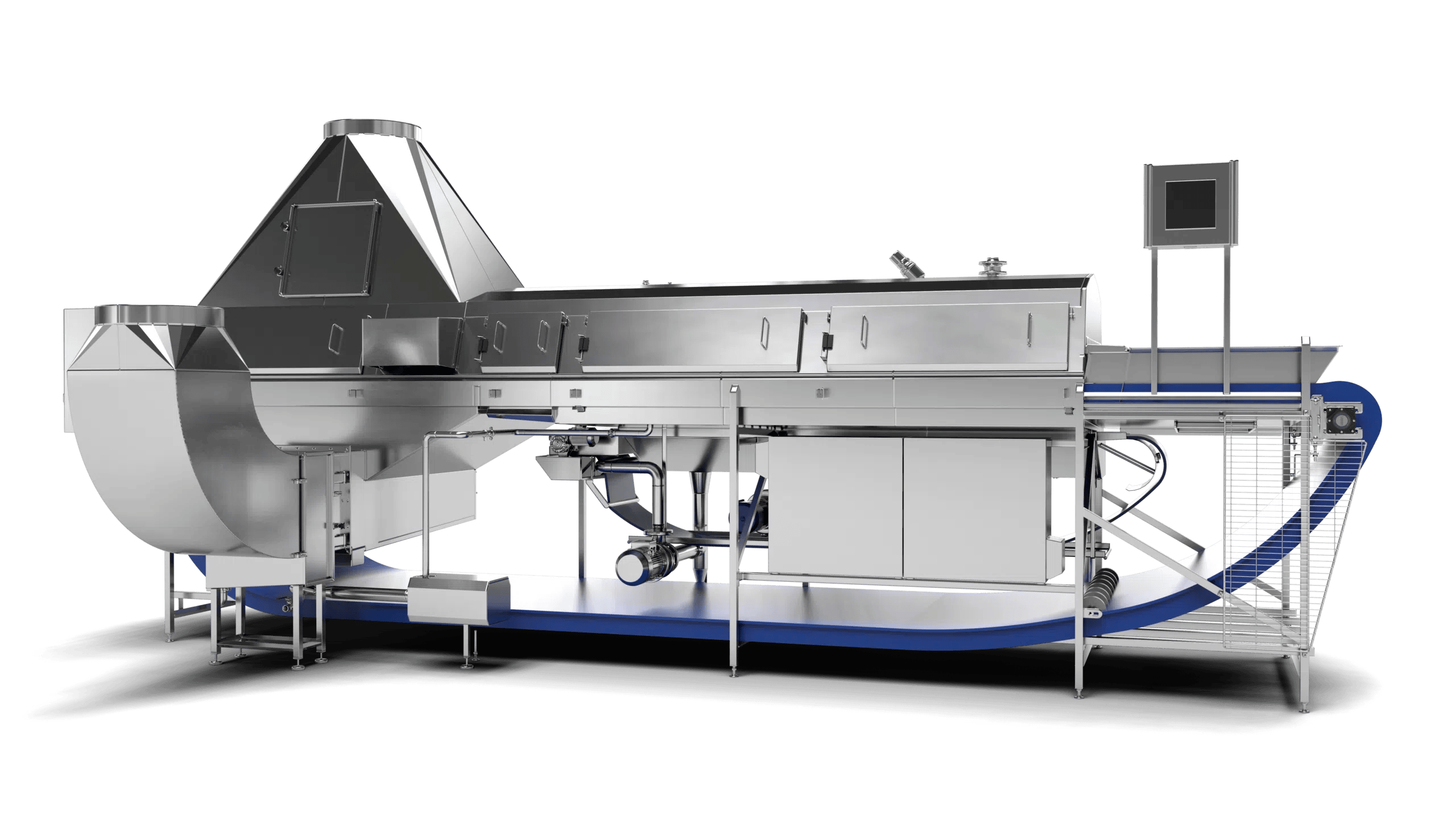

BACW

If you require a temperature below 20-25°C, you have the option to incorporate a water-cooling segment following the air-cooling phase. This segment can be connected to a Baudelot chiller for recirculating cooling water. By doing so, you can achieve a product temperature of approximately 10°C while keeping water consumption at a minimal level. Further reductions in product temperature can be achieved by extending the cooling section.

Advantages

- Low risk of product contamination even

after long operating hours - Integrated blancher and cooler

- No product damage

- High yield

- Uniform blanching

- High degree of flexibility with regard to

blanching time and temperature - Evaporative air-cooling section incl. fan

- Additional lowering of product temperature

by means of recirculated chilled water, option - Customer-adapted design

- Hygienic design makes cleaning easy

- Capacity from 2 to 30 t/h

Technical Data

| BAC Basic Version | BAC 6 | BAC 8 | BAC 10 | BAC 12 | BAC 16 |

| Nominal Capacity for Green Pears Kg/h | 6,000 | 8,000 | 10,000 | 12,000 | 16,000 |

| Overall Length m | 8 | 10 | 12 | 14 | 18 |

| Steam Consumption max. Kg/h | 1,100 | 1,400 | 1,700 | 2,000 | 2,600 |

| Water Consumption max.m3/h | 0-3,5 | 0-4 | 0-4 | 0-5 | 0-6 |

| Nominal Power Consumption*) kW | 18/36 | 24/48 | 30/60 | 36/72 | 48/96 |

Contact a specialist

We have people all around the world who can help.

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen

Product gallery

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.