Modern processing of frozen vegetables requires modern technology

For years, the food processing industry has been fighting to put processed/frozen vegetables on the consumer’s table which are of a quality comparable to that of fresh vegetables. At the same time, manufacturers are faced with stricter environmental demands in the form of increased prices for energy and restrictions on waste water.

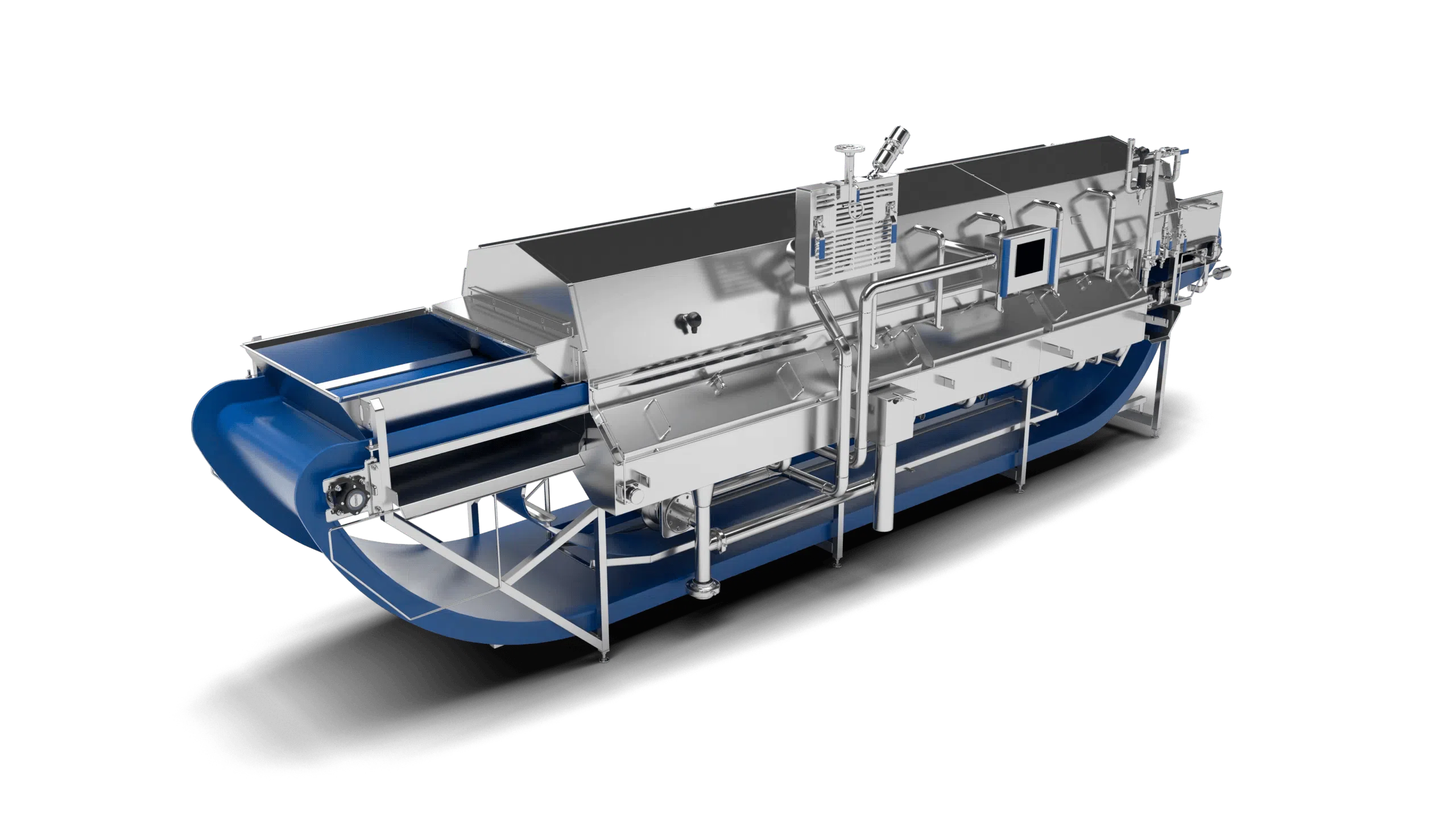

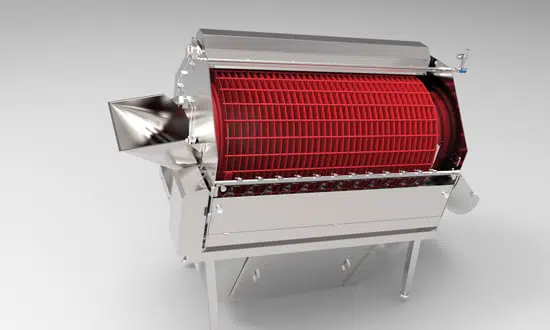

The Cabinplant blancher programme consists of a wide range of models divided into three main categories. With this extensive range of blanching/cooling systems Cabinplant are able to fulfill any blanching/ cooling requirement you may have.

Get contacted by one of our experts

Fill out the form and one of our experts within frozen vegetables and berries will reach out shortly.

"*" indicates required fields

New standards for processing of vegetables & berries

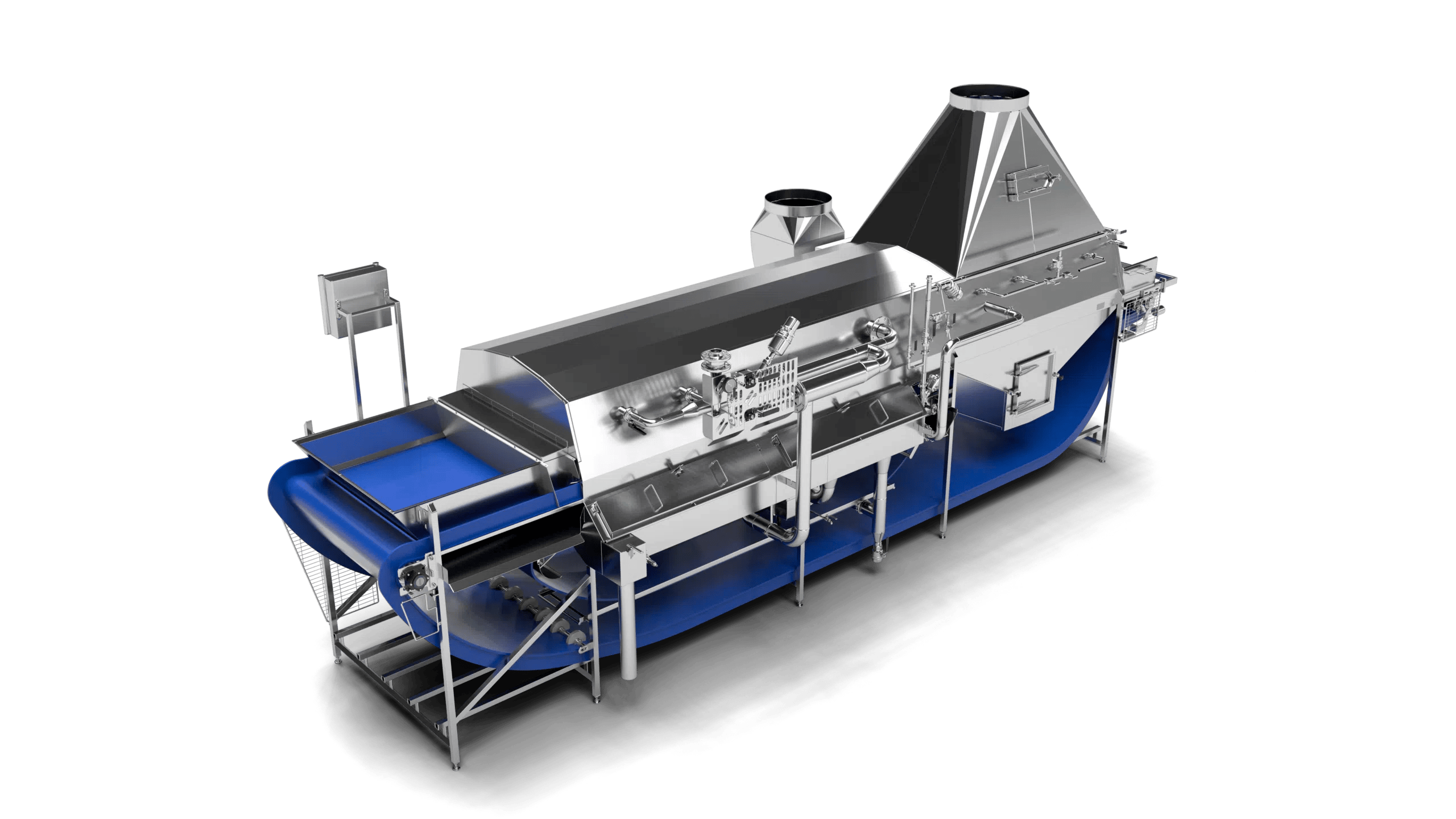

With the development of our unique integrated blanching/cooling system, which has been an international success ever since its appearance in 1981, Cabinplant have solved the problems with utilities. Not only have we set new standards for product quality, but we have also managed to reduce water and energy consumption to an absolute minimum.

The Cabinplant blancher programme consists of a wide range of models divided into three main categories. With this extensive range of blanching/cooling systems Cabinplant are able to fulfill any blanching/ cooling requirement you may have. Our blanchers work efficiently with capacities ranging from only 1 t/h up to 30 t/h. Even if your blanching requirements cannot be met by our standard range, Cabinplant’s experienced and creative engineers are always ready with alternative solutions.

Energy-saving & water-reducing blanching solutions

Increase freezer capacity and running hours

High quality vegetable processing equipment

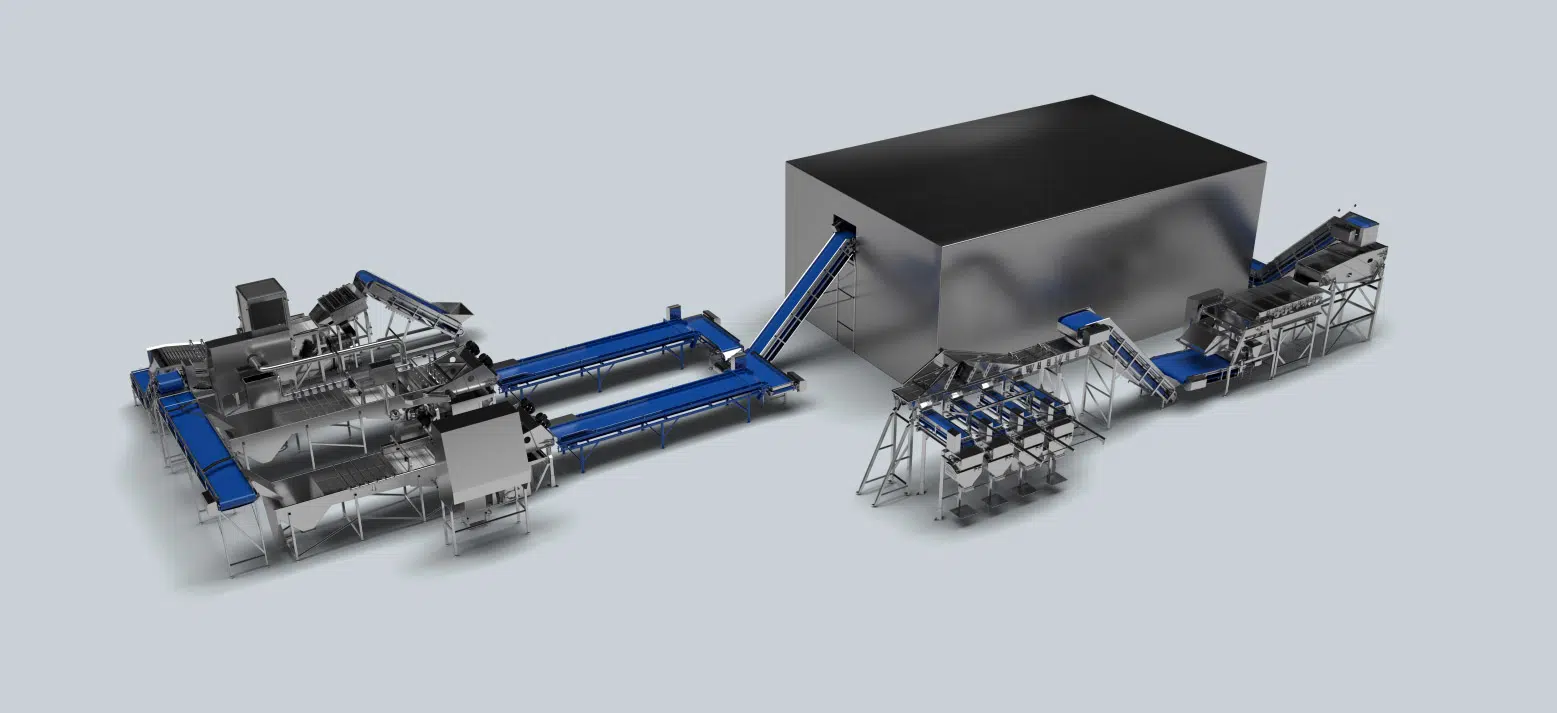

Selected complete processing solutions to improve your production

Tailor-made water and energy-saving processing equipment for vegetables and berries

The delicate nature of most vegetables and berries requires gentle processing equipment in order to maintain their important nutritional properties and great taste. Our vegetables & berries processing equipment will help your business with that.

Because of the accurate water flow control, product temperature and retention time in the blanching process, taste, colour, nutrients and vitamins are retained in the product.

When products quality and sustainability go hand-in-hand

For years, the food processing industry has been fighting to put processed/ frozen vegetables on the consumer’s table which are of a quality comparable to that of fresh vegetables. At the same time, manufacturers are faced with stricter environmental demands in the form of increased prices for energy and restrictions on waste water.

One of our key competences is high-quality vegetable processing equipment with low energy and water consumption. With the development of our unique integrated blanching/cooling system Cabinplant has solved the problems with waste. Not only have we set new standards for product quality, but we have also managed to reduce water and energy consumption to an absolute minimum.

References

Cabinplant has backed us up all the way through our project; from the preliminary tests in Denmark up until the final running-in of the line after industrial trials on site. The teams have proved receptive to our demands and were able to meet our requirements. During the start-up phase, Cabinplant has supported us on site and by remote service to obtain our goals.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.