About the Customer:

Our customer is a prominent producer of both turkey and poultry meat. They have previously invested in Cabinplant Packing Lines designed for packaging fresh and marinated meat in trays, and decided to return to us, when needed a flexible packing line for IQF nuggets.

The Challenge:

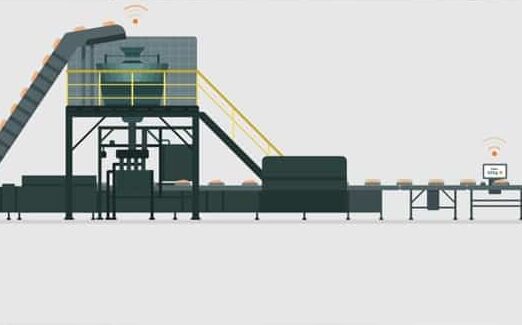

The latest challenge our customer faced was to develop a highly flexible packing line for their individually quick-frozen nuggets. These nuggets were intended to be packaged in two ways: in pillow bags and subsequently packed into trays, both with manual packing and machine packing. This required a very adaptable solution that could handle all packaging methods efficiently.

The Solution:

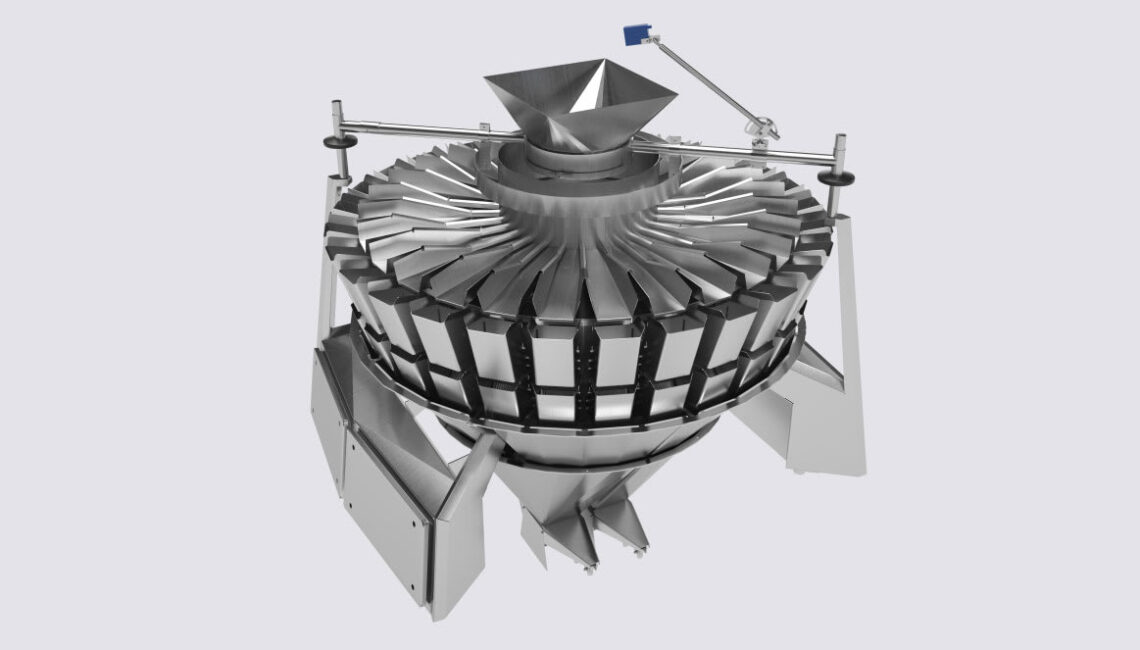

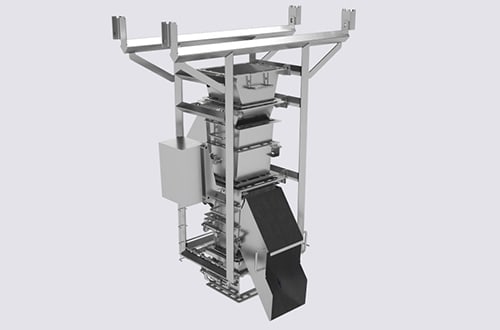

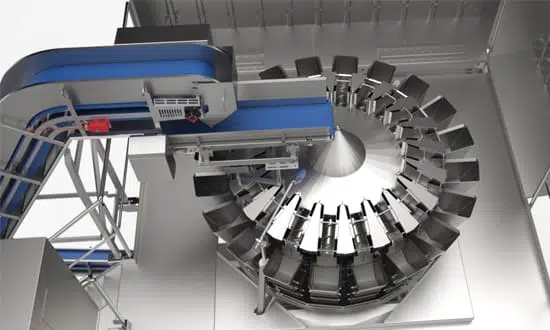

Our solution made it possible to seamlessly address the costumer’s unique packaging requirements. The heart of this solution is a distribution conveyor with two outlets, both a movable Multihead Weigher and Infeed elevator which provides the necessary flexibility to accommodate different packaging formats.

To ensure the precise and efficient weighing and filling of the IQF nuggets, we integrated the movable Multihead Weigher into the system. This Multihead Weigher was equipped with two collection hoppers/timing hoppers, constructed from sound-damping materials to reduce noise levels and improve the overall working environment. These two hoppers, tailored to situations A) and B), enabled swift and convenient production changeovers. This adaptability allowed our client to seamlessly switch between packaging pillow bags and trays, ensuring minimal downtime and maximum efficiency during production.

The Result:

The end result was a highly efficient and comprehensive packaging solution that exceeded the client’s expectations. The customer was satisfied with the performance and adaptability of the system but also appreciated the dedication and expertise our team brought to the project. Another successful collaboration with a returning customer was made possible with the use of only the best quality, new innovation, and our ability to make tailored solutions to meet our customer’s needs.

Benefits

- All-in-one process

- Space saving

- Better yield

- Less labor cost

- Easy to clean

- Full tracking of raw materials and finished products

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.