Weighing Mixing Automation

Marinating of meat and poultry made easier

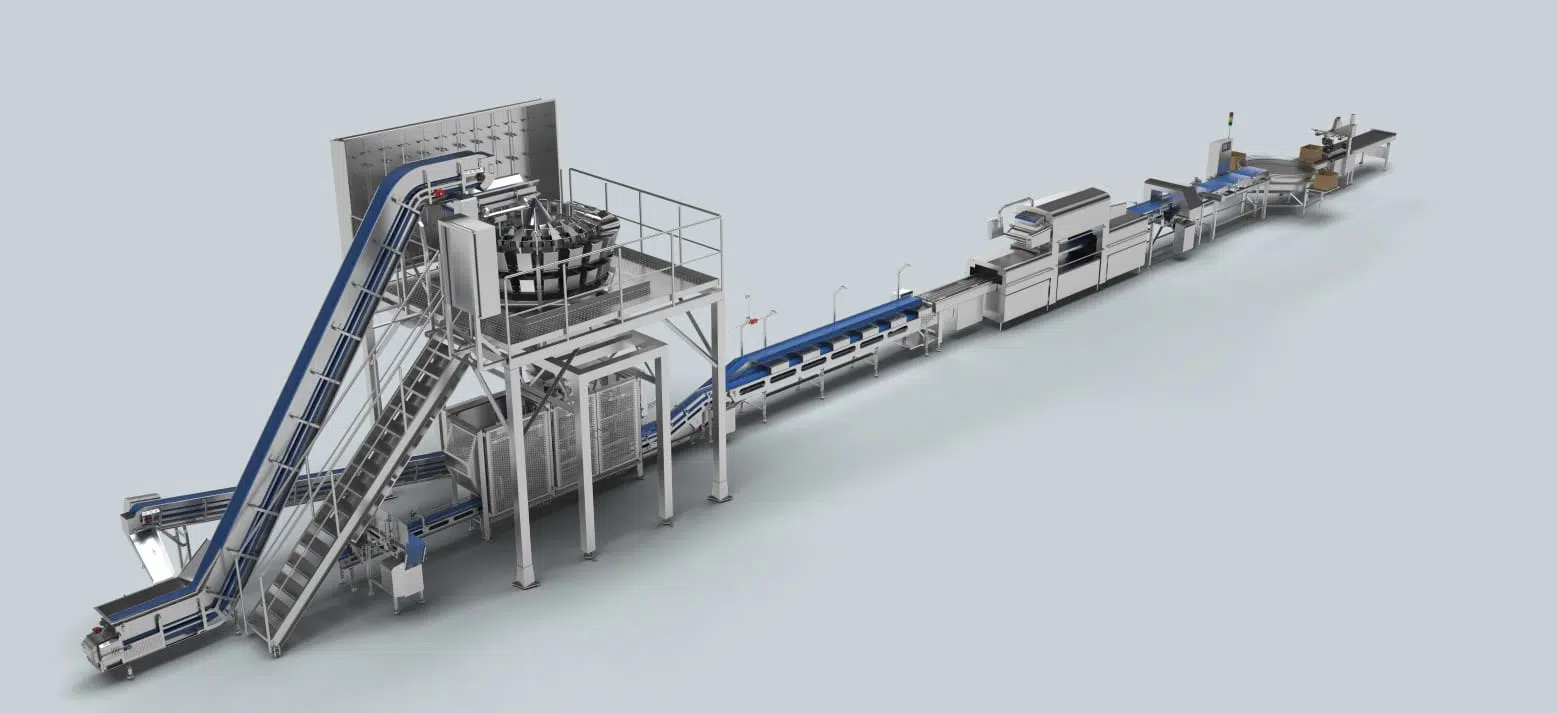

Marinating meat and poultry products typically requires extensive cleaning of production equipment, resulting in increased spillage of marinade. However, the Cabinplant Marinating System significantly reduces the amount of necessary spillage and cleaning required after marinating.

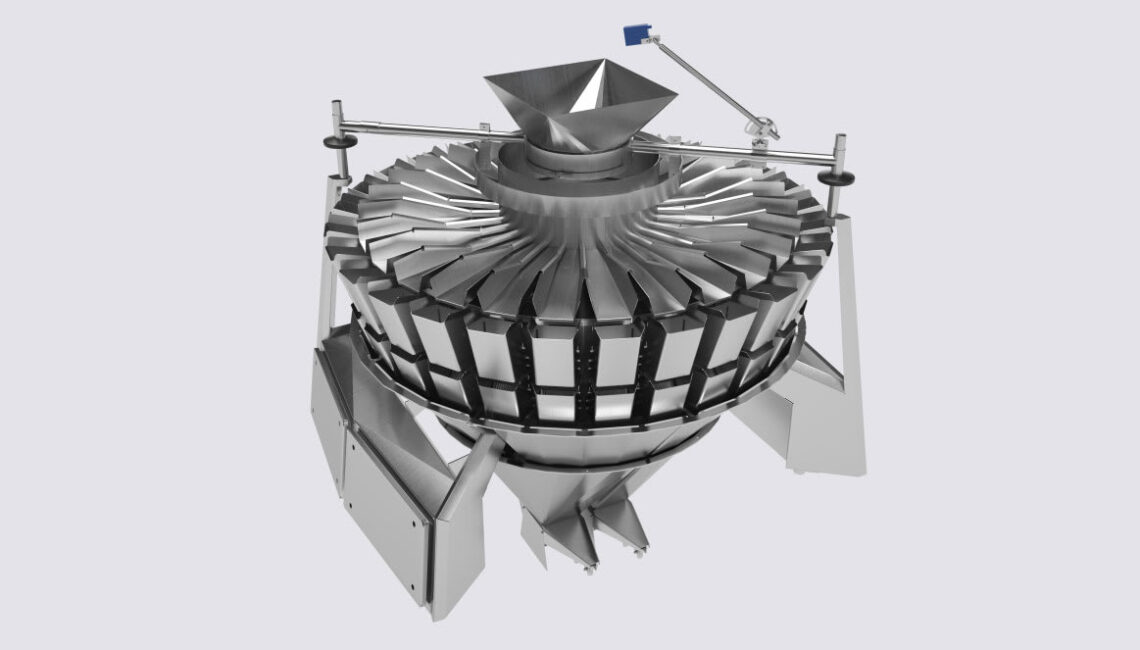

Our Marinating System is placed in line with the packing line. Still, compared to other solutions, our solution is positioned after the portion weighing, which means that the Multihead Weigher and conveyors are not submerged in marinade.

Download our brochure below and learn more about our Marinating System.

"*" indicates required fields

Reduce cleaning time by up to 80%

Meets market demands for small batch production

Fast change-over time - less than 20 min.

Information about our Marinating System

Post-marinating allows for small production batches

Supermarkets require frequent deliveries of fresh and varied marinated products to display on the counter. For producers, this requires a production setup that enables production in small batches and frequent shifts of marinades.

However, marinating poultry products usually requires time-consuming cleaning of production equipment, such as the tumbler, elevator, Multihead Weigher, tools for the weigher, and the marinade dispenser.

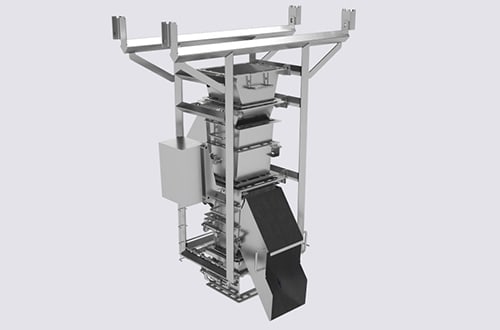

The Cabinplant Marinating System disrupts the process because marinating is done after the portion is weighed. The marinade is added to the fresh meat using a special mixing tool just before it is dropped into the tray. Only the tool and the dispenser need to be cleaned, allowing a much more frequent shift of variants.

Proven solution

The Cabinplant Marinating System was introduced to the market in 2015 and has been installed at several large poultry processors in Europe. Thus, the system has already proven to be an effective and cost-efficient solution for marinating fresh products, contributing to considerable cost savings, increased production flexibility, and a better working environment.

Features & benefits

- Excellent weighing accuracy

- No giveaway when handling small negative tolerances

- No spillage

- Minimum maintenance

- Easy cleaning

- No marinade on conveyor and multihead weigher

- Fast return on investment

- Meets market demands for small batch production

Functionality

- In-line marinating of meat products

- Direct filling in pre-made trays or thermoformed trays

Capacity & Use

- Up to 60 portions/minute depending on portion size

- Meat & Poultry

Contact a specialist

We have people all around the world who can help.

Contact us today to learn more about you can bring down costs and increase flexibility when marinating meat and poultry

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.