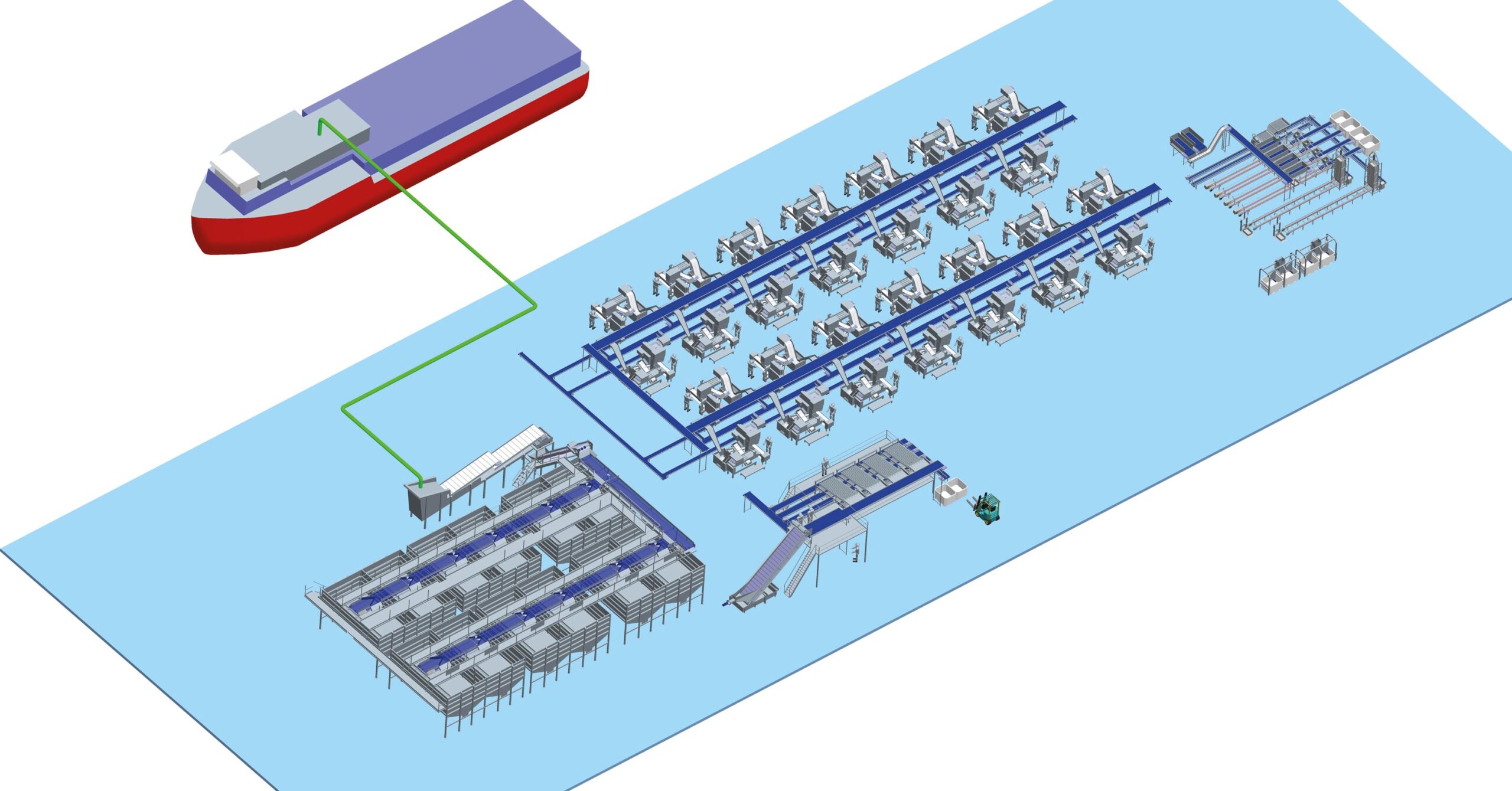

Complete processing line for herrings

Impact

Our efficient packing solutions are designed to improve your business.

Industry know-how

With industry know-how from 40 years of experience, we are experts at putting all the right pieces in place

Innovative ideas

Cabinplant draws on an in-depth knowledge of the seafood industry to help processors deliver a variety of innovative solutions

Minimizing waste

Cabinplant specializes in developing processing lines that minimize waste through gentle and optimal treatment of raw material

Complete processing

line for herrings

Cabinplant provides complete herring processing lines with capacities up to 70-80 tons per hour. These include total solutions for packing of whole, round fish in plastic containers, as well as complete systems for handling of fillets – fresh or cured. In addition we provide complete lines for processing of matje herring.

Cabinplant’s solutions for herring include:

- Receipt of fish in bulk direct from the ship

- Weighing of incoming fish

- Grading in up to five different sizes

- Distribution of fish to filleting machines

- Gilling of herring (for matje herring)

- Dry feeding systems for filleting machines

- Vision systems for filleting machines

- Transport systems for collection of cut fillets

- Systems for salting of fillets in barrels and vessels

- Curing of fillets in barrels and vessels using a stirring unit or a rolling system for barrels

- Packing systems for fillets and whole, round fish in barrels, boxes, trays etc. using batch weighing and multihead weighing

- Handling of waste

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Our cooperation with Cabinplant has been dynamic, professional and highly effective. They understood our business and our requirements and we got the tailored solution we needed...

Products in solution

Customize your solution

Designing food production equipment is often a question of combining various existing technologies in new and innovative ways. That’s one of our core skills - to meet the challenges you give us, while applying everything we know about automation, robotics and mechanical engineering.

We use our skills and long market expertise in designing a production line which is tailor-made to your needs and specifications. And of course, everything we design is constructed by top specialists.

Contact a specialist

We have people all around the world who can help.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.