Optimization

Vision system

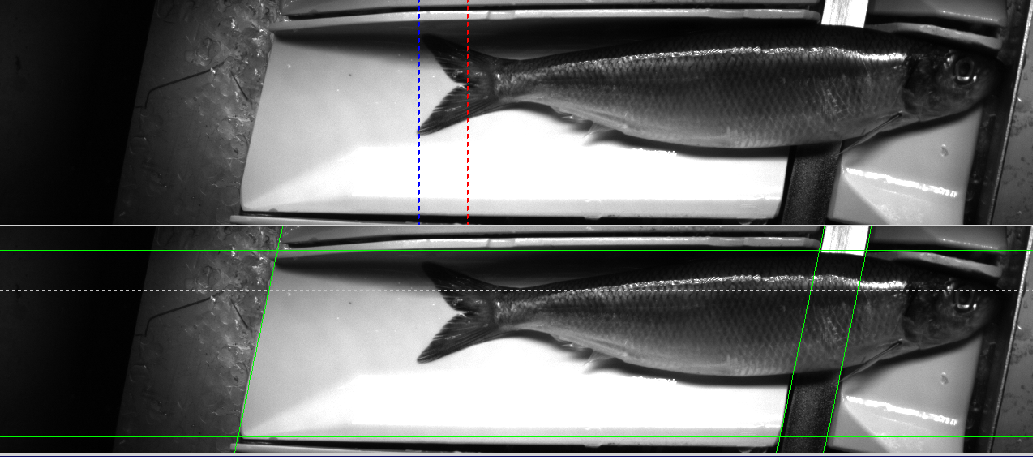

The Cabinplant Vision System is a camera-operated fish sorting system for existing filleting machines, designed for the surveillance of product infeed to Baader or VMK filleting machines.

The system controls the entire filleting machine, which means that it checks input and output – what goes in, comes out. If not, the line stops! It will also attempt to optimize the amount of fish on the pocket conveyor serving the filleting machine. For instance, if the fish block the feeder to the filleting machine, the outlet gates of the feeder will be opened.

The solution can be mounted on existing filleting machines with only very few changes to the existing line setup.

Reduction from 1 to 0 operators

Existing set-up can be used

Uses self-teaching method

Information about our Vision System

Fast and efficient

The system operates by taking a picture of each fish to determine if it is the correct species, the proper size, whether it is whole or half, and whether it is placed correctly on the conveyor before cutting, among other factors. Unwanted fish are rejected as waste or recirculated in the system if they were rejected due to incorrect positioning on the conveyor, e.g.

Optional: The system can also be equipped with a dry feeding conveyor to further enhance the feeding efficiency of the filleting machine.

Application

- Herring

- Mackerel

Capacity

- Up to 320 trays per minute

Features & benefits

- Reduction from one to zero operators

- The existing filleting machine set-up can be used

- Full statistics function on every fish

- PC-based control enables software upgrade

- Implemented the self-teaching method

- Switch between the production of herring and mackerel

Functionality

- Detection of belly-turned fish

- Detection of foreign species

- Detection of double fish

Contact a specialist

We have people all around the world who can help.

Product gallery

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.