Weighing Automation

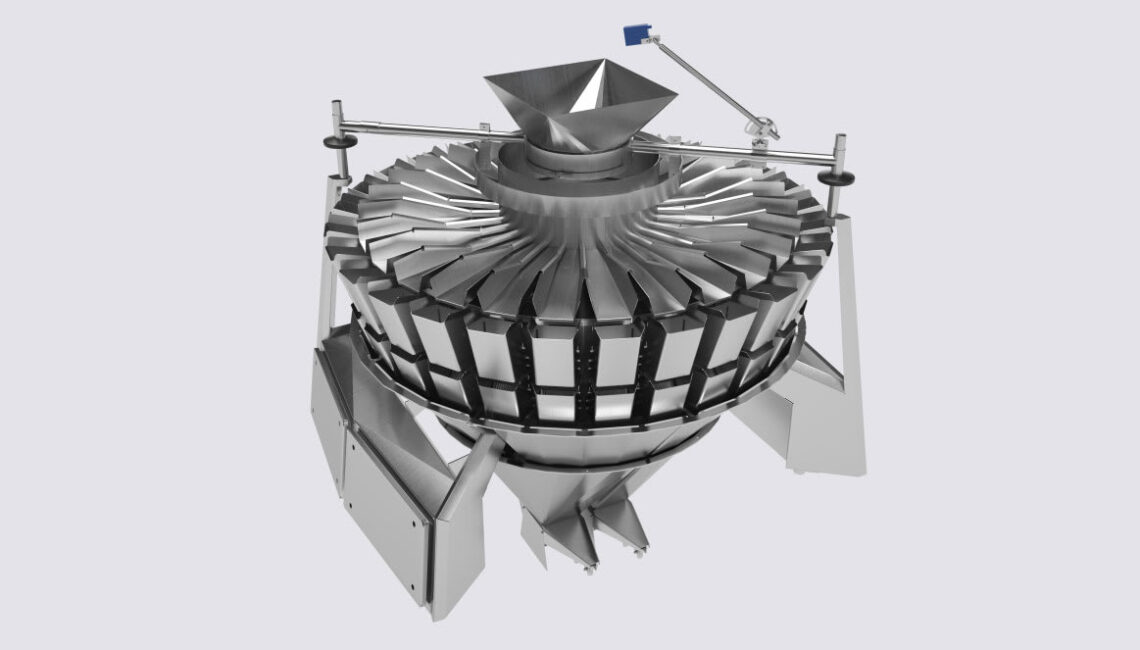

Multibatcher - weighing and batching at high speed

The Cabinplant Multibatcher is developed based on 50 years of experience within the food industry. The solution is specifically designed to meet individual requirements for handling large portions of products.

Cut your giveaway by up to 75 %. Speed, flexibility, and accuracy are key parameters when optimizing your production costs.

Our fully automatic Multibatcher performs accurate high-speed

combinatorial weighing and handles portion sizes of up to 35

kg of meat or meat by-products.

The accurate weighing of batch sizes reduces giveaway significantly compared to other systems and improves your return on investment.

The Cabinplant Multibatcher is tailor-made based on the product

size and batch size according to customer request and available

either as a stand-alone unit for automatic or manual bagging,

box packing or filling into thermoformed packages, or as part of

a complete packing line.

Download our brochure below and learn more about the Multibatcher.

"*" indicates required fields

Reduces giveaway by up to 75 %

Ideal for packing export or food service products

Automates batching and cuts labor costs

Information about our Multibatcher

Make the most of your raw product

With efficient high-speed combinatorial weighing and handling of portion sizes up to 35 kg, the Multibatcher can easily process complex and demanding products.

Functionality of the Multibatcher

The Multibatcher can process up to 12 batches per minute or up to 720 batches per hour, ensuring you automatic, consistent, and reliable handling of your raw material, 24/7, all year round. The solution is tailor-made to your specifications and can be integrated into existing packaging lines or used as a standalone unit.

The Multibatcher is suitable for a wide range of products, including meat, poultry, and fish products.

Application

- Poultry (bone-in or boneless)

• Drumsticks

• Thighs

• Breast

• Breast caps

• Saddle

• Leg quarters

• Whole chickens - Meat (pork, beef)

• Feet

• Lacones

• Riblets

• Neckbone

• Hack

• Belly trim

• Trim - Fish

• Fresh pelagic fish

• Frozen pelagic fish

Features & benefits

- Accurate combinatorial

high-speed weighing - Reduced giveaway (10 times

less than other systems) - Cuts labor costs to a minimum

- Hygienic design – easy to clean

- Logic process interface

– easy to operate - Rapid change to another product

by using recipe control.

Dimensions

Functionality

• Batch size from 2 – 35 kg

• Recipe control

• Data collection and statistics

• PLC control of equipment

• Capacity up to 12 batches/min.

depending on batch size

| Dimensions | Multibatcher | |

| Type | MB 18 | MB30 |

| Length | 3400 | 3400 |

| Height | 2400 | 3000 |

| Width | 1550 | 1750 |

| Capacity | ||

| Batch size max. kg | 10 | 35 |

| Hopper volume liters | 18 | 30 |

| Hopper size (LxWxH) mm | 200x120x200 | 400x240x200 |

| Capacity max. batches/min. | 12 | 12 |

Contact a specialist

We have people all around the world who can help.

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.