About the client

Saeby Fish Canners is the world’s leading and most modern mackerel factory.

The Challenge

Sæby Fiskeindustri is the world’s leading and most modern mackerel factory. It produces 100 million cans of mackerel each year, including the company’s very popular mackerel in tomato. The visionary partnership between Sæby Fiskeindustri and Cabinplant is one of the key reasons behind this success, as the two companies have continuously challenged each other and experimented with new ways to improve things and make them more efficient through the automation of processes and simplification of workflows.

The solution

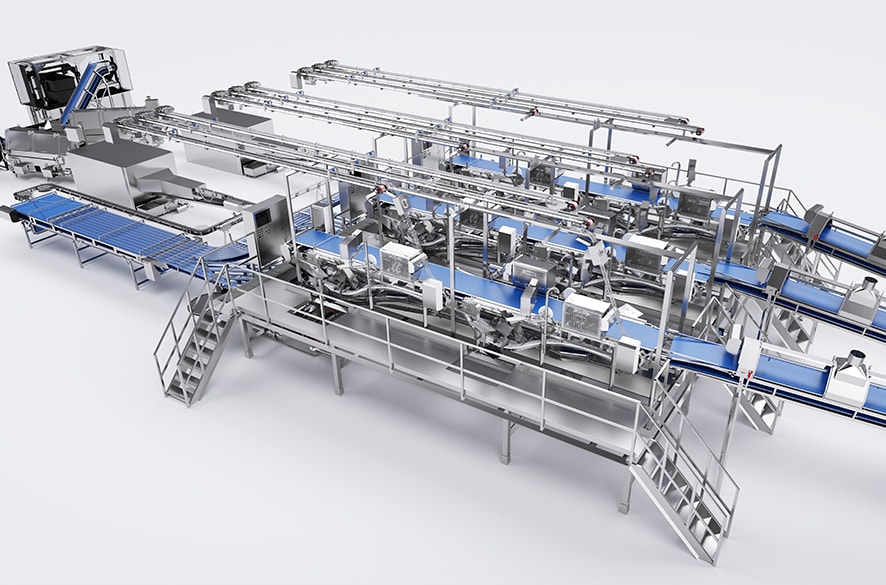

Cabinplant delivered a large part of the production equipment used in the new mackerel factory, which was first opened in 1988. It was Cabinplant that developed the “green”, chemical-free de-skinning methods which loosen the mackerel skin through a short treatment process using boiling water and steam.

Cabinplant supplied the entire processing chain, which includes de-skinning, thawing and cooking the mackerel, as well as filleting; the semi-automatic packaging of fillets into cans, and adding the sauce.

The result

All production lines are updated on a continuous basis and Saeby remains the most environmentally-friendly and cost-effective factory for the production of canned mackerel in the world today.

“When I look at Cabinplant from outside, what I see is a group of professionals with an immense knowledge of the products that are produced within the fish industry. Cabinplant is the industry specialist when it comes to equipment for canning fish, and the company is one of our key suppliers,”

Benefits

- Reduction of labor

- Increased food safety

- Less give-away

- Full tracking of raw materials and finished products

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.