About the Customer:

A valued brown crab processing customer for more than 25 years, and one of the largest producers of fish and seafood in Europe. Their main products are crabs and other top-quality shellfish.

The Challenge:

Our customer needed a new crab factory to meet the increasing demand and aimed to minimize transportation costs by building it closer to where the crabs are caught.

An increasing demand for crabs is not surprising, as their taste is excellent. Furthermore, crabs are the most significant protein source found in the ocean, and they are not subject to quotas. They are only caught as wild catch and not seen with bottom trawling, but they are caught in pots, which does not damage the ecosystem.

A significant challenge was to meet the demand for brown crab processing, while also having the opportunity to become more eco-friendly by reducing transportation and increasing the sale of less overfished species like those in the ocean.

The Solution:

In addressing the need for a new crab factory, our customer decided to trust us again. A collaboration that combined their knowledge of brown crab processing and our expertise in machinery. Together, we have consistently developed equipment that aligns with industry needs.

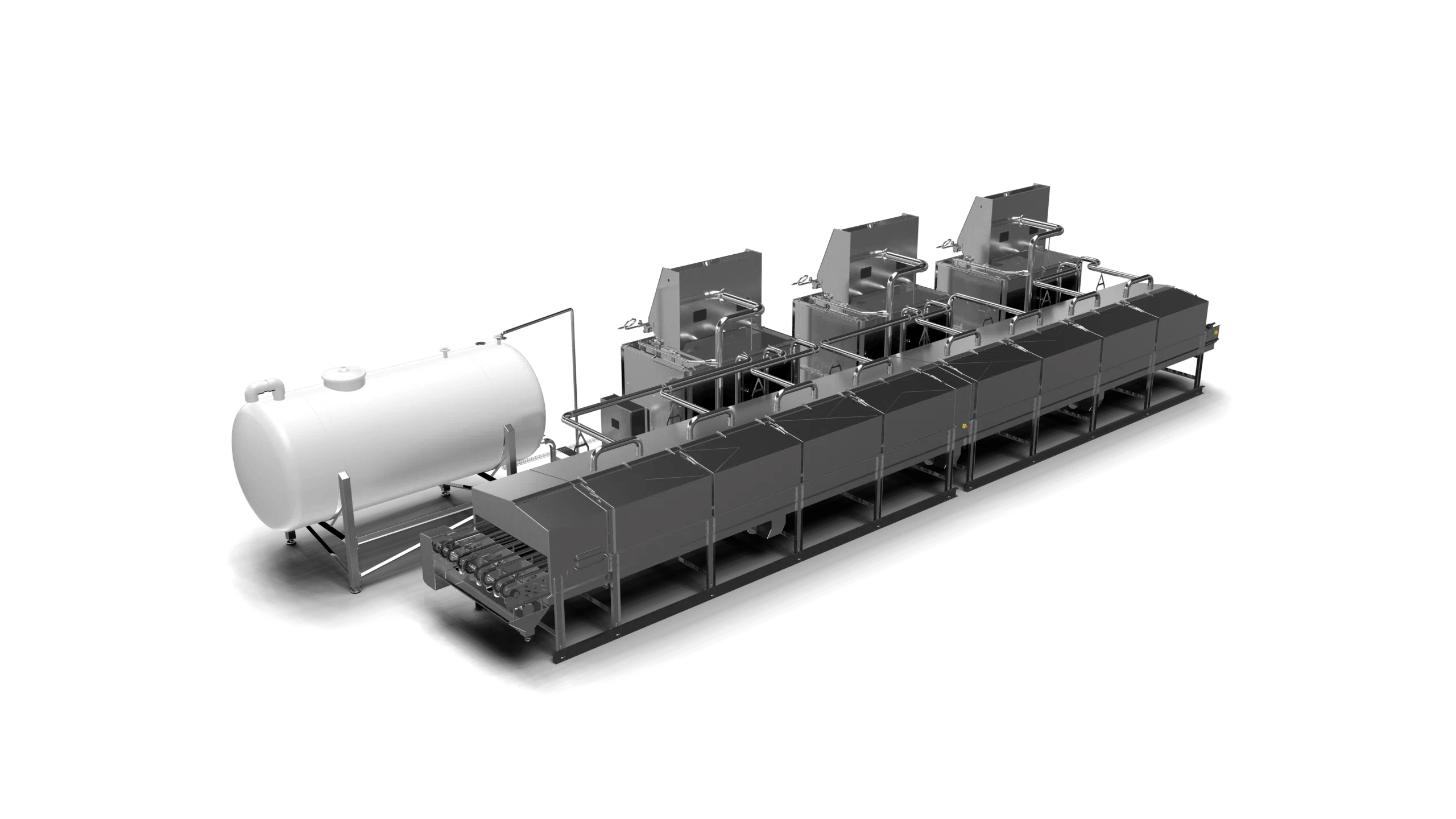

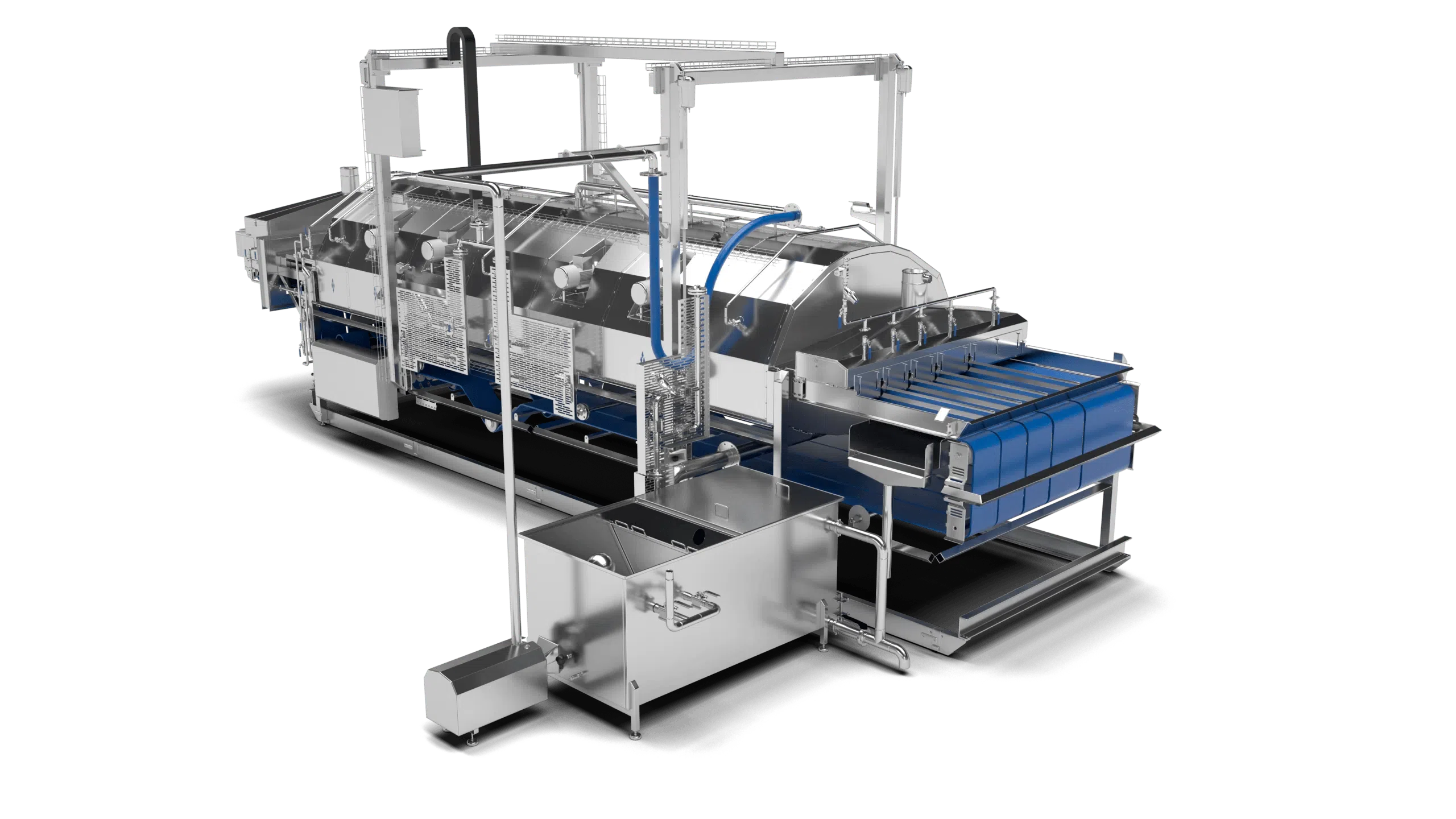

Our Seafood Cooker has a large belt that can be divided into multiple belts. This means the belts can operate at different speeds and be split into several smaller belts, a few large belts, or a combination of these. This setup allows for anywhere between 1 and 5 belts to run simultaneously at different speeds, offering significant flexibility for producing smaller batches and easily adapting to variations in input.

The Result:

A brand new factory for brown crabs has strengthened our partnership, with our collective know-how serving as the foundation for constructing a new crab factory in Europe.

Benefits

- Minimum use of operators: 4-5 persons can run the line

- High traceability when using baskets

- Ability to run different sizes simultaneously

- Top-lift for quicker cleaning and maintenance

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.