Heat treatment Dosing/Filling Automation

Spring roll processing

Our innovative solution in spring roll processing gives you tailor-made business benefits. Costs and quality. Two paramount words in spring roll processing.

The taste of a freshly hand-rolled spring roll combined with a low total cost of ownership is a winning formula. With over 30 years of specialized experience, we offer unique and efficient customized solutions tailored to your needs, utilizing proven technology and delivering enhanced benefits.

Experience unparalleled business advantages with our advanced processing systems.

Produce your entire product range on a single flexible line

30 min downtime on product changeover

Manual labor reduced to two operators

Reduce your total costs and increase your product quality

-

Time reduction to 30 minutes in transition and reaction time for specific needs, such as recipe and size changes.

- The production area remains spacious, as the machine’s compact design requires less space than traditional operations and machines.

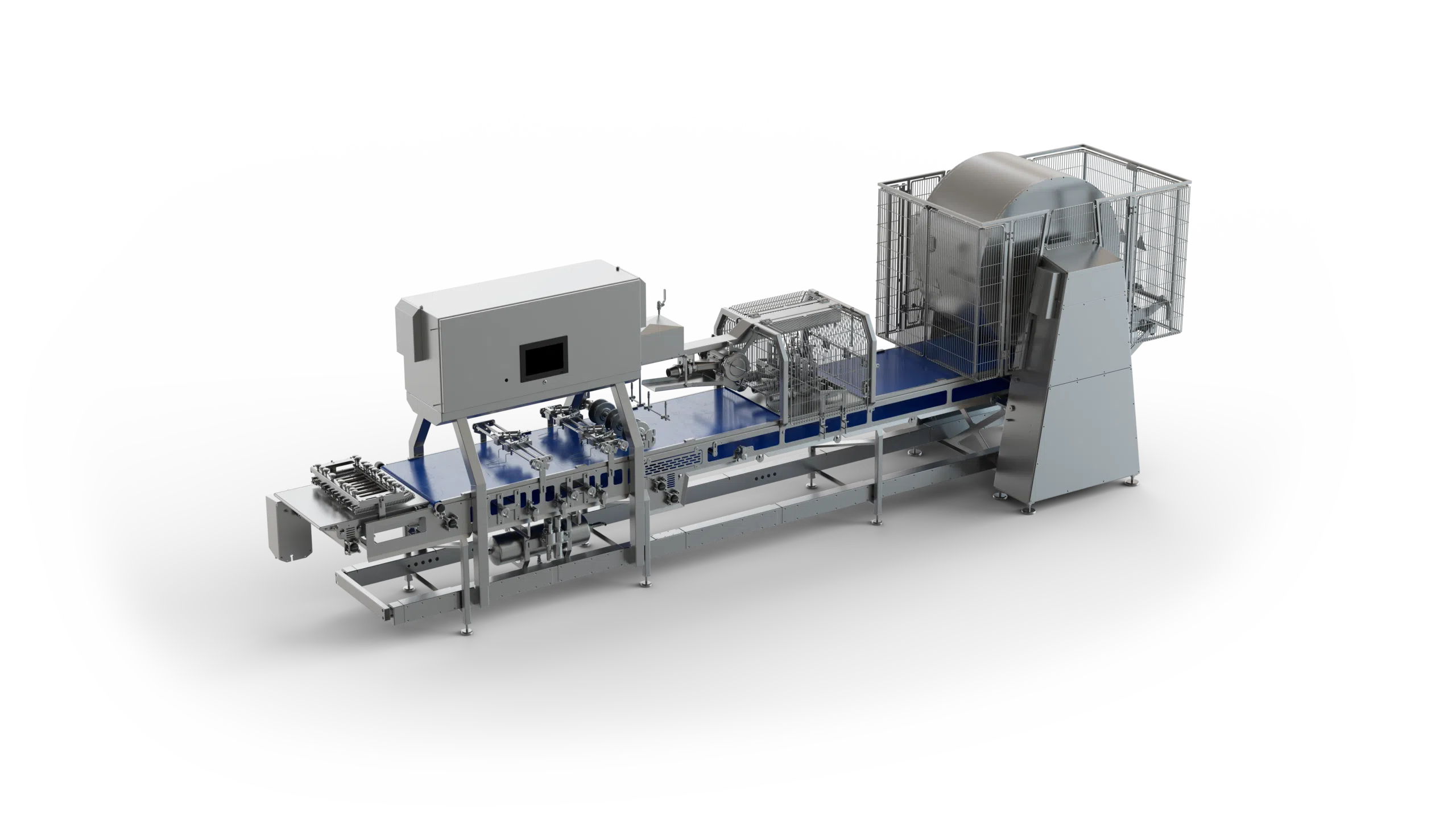

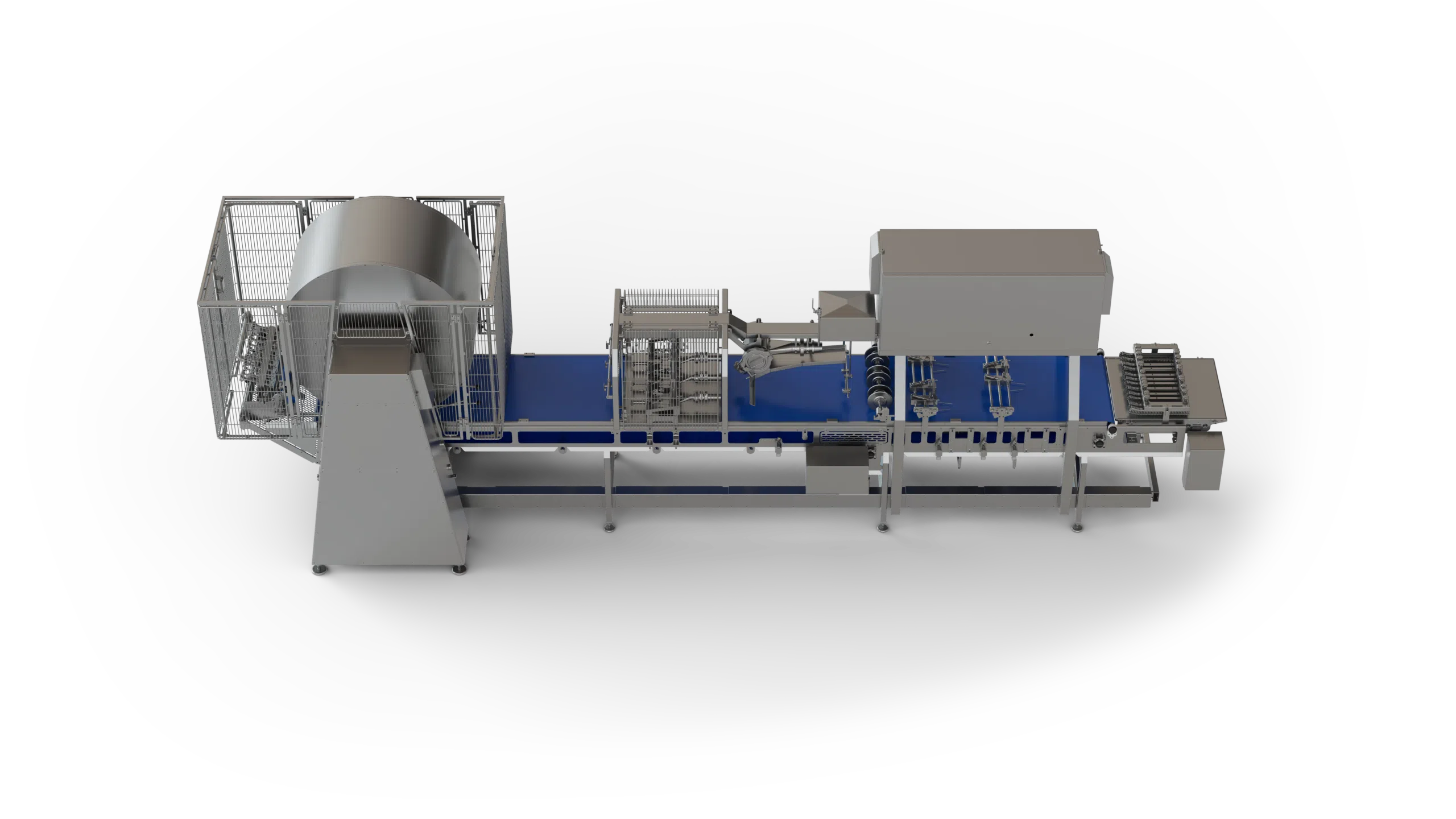

- The Spring roll machine with a standard drum has the following dimensions: 2177 in height, 6510 in length, and 1881 in width.

- The Spring roll machine with a large drum has the following dimensions: 2777 in height, 6610 in length, and 1981 in Width.

- Reduction of waste and improved product consistency through optimized raw material usage, precise filling deposition, and consistent sheet thickness

- Enhanced food safety results from the elimination of human cross-contamination.

- Enhanced productivity is achieved through its user-friendly operation.

-

Productivity is improved due to easy access for cleaning, minimal maintenance, and labor savings.

The spring roll machine consists of the following:

- Batter pump

- Dough dispenser

- Baking drum

- Spring roll Sheet folding conveyor

- Filling dispenser (incl. vacuum filler)

- Pneumatic folding

- Roller arrangement

Features & benefits

- Time reduction regarding transition

- Compact design

- Greater product homogeneity

- Reduction in waste

- Increased food safety

- Increased efficiency

- Low labor costs

Line capacities are from 120 to 240 rolls per minute.

Standard Drum

| Dim.mm | Double lane | Triple lane | Quadruple lane | Quadruple/Double lane | Quadruple / Triple lane |

| Pcs./min | 120 | 180 | 240 | 240/120 | 240/180 |

| Width of sheet | 300 | 195 | 145 | 145/300 | 145/195 |

| Baking drum (Ø) | 1200×655 | 1200×655 | 1200×665 | 1200×655 | 1200×655 |

Large Drum

| Dim.mm | Double lane | Triple lane | Quadruple lane | Quadruple/Double lane | Quadruple / Triple lane |

| Pcs./min | 120 | 180 | 240 | 240/120 | 240/180 |

| Width of sheet | 360 | 210 | 180 | 180/360 | 180/210 |

| Baking drum (Ø) | 1800×750 | 1800×750 | 1800×750 | 1800×750 | 1800×750 |

Contact a specialist

We have people all around the world who can help.

Product gallery

Want to automate your spring roll processing? Contact us to learn more about your possibilities.

From batter to crispy spring roll with no hands involved

Did you know there are a lot of advantages in investing in an automated spring roll line from Cabinplant including:

- Higher food safety due to minimized risk of cross-contamination

- Decrease in recruitment costs

- Save production space

- Downtime only 30 min pr product turnover

Sign up on this form and learn more about you can grow your business with an automated solution for your production of spring rolls.

Send the result

Your results have been sent

Calculated as an average

Size of the spring roll sheets? -; 145 millimeters

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.