About the Customer:

The customer is a prominent company specializing in processing fresh fruit and berries in Egypt.

The Challenge:

The customer searched for an automation solution to enhance food safety and maximize strawberry yield during processing. The primary concern revolved around improving the washing process and implementing an efficient cleaning solution to handle sand and leaves.

The Solution:

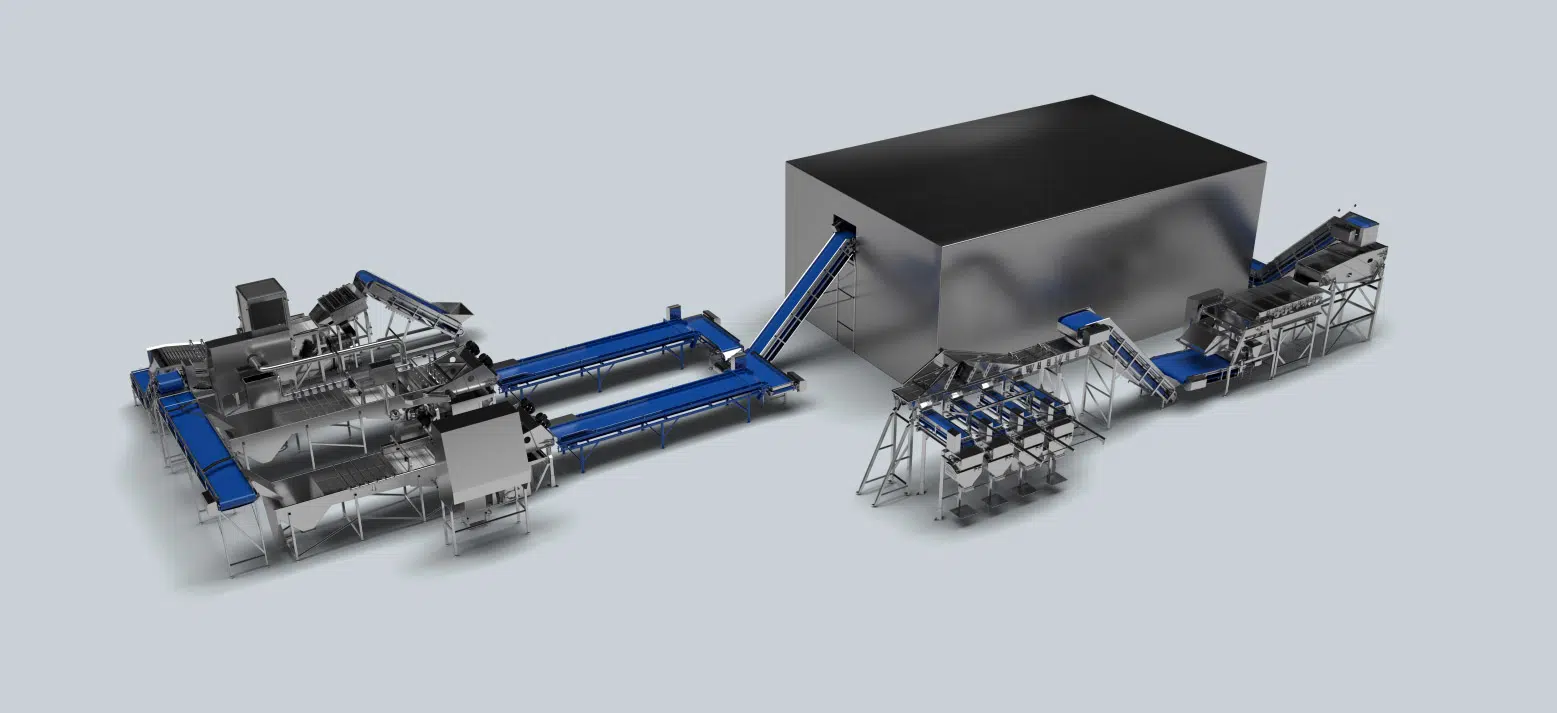

The solution to enhance the cleaning process, preserve product quality, and maximize yield in strawberry processing involved implementing a Cabinplant strawberry line. This versatile line is designed for pre- and post-freezing stages and boasts a processing capacity of up to 3,500 kilograms of whole strawberries per hour. It features an upgraded cleaning system that includes advanced washing and air-cleaning components, ensuring high-quality products.

The Result:

The customer has significantly decreased manual labor and can produce a high-quality product. Additionally, the machine is made with high-quality food safety materials, ensuring a reliable machine with great results every time. Further, the washing state of the Strawberry line ensures that even the smallest leaves and debris are removed and keeps food safety to the highest standard. Furthermore, a sorting and size station ensures that the product is uniformly packed.

Benefits

- Gentle Treatment

- Comprehensive Cleaning

- Efficient Workflow

- Minimum Noise level

- Optimal Glazing

- Customizable Solution

- Easy Cleaning

- Hygienic Design

- Cutting-Edge Technology

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.