About the Customer:

Our customer is a market leader in Europe in the production of fresh convenience salads and convenience fruit and vegetables.

The Challenge:

Packing of fresh salads including various kinds of topping products into trays to form a ready-to-eat salad ready for retail sale often requires a lot of labor intensive processes. The challenge here was to automate the production in order to reduce labor costs and increase food safety by cutting human handling to a minimum.

The Solution:

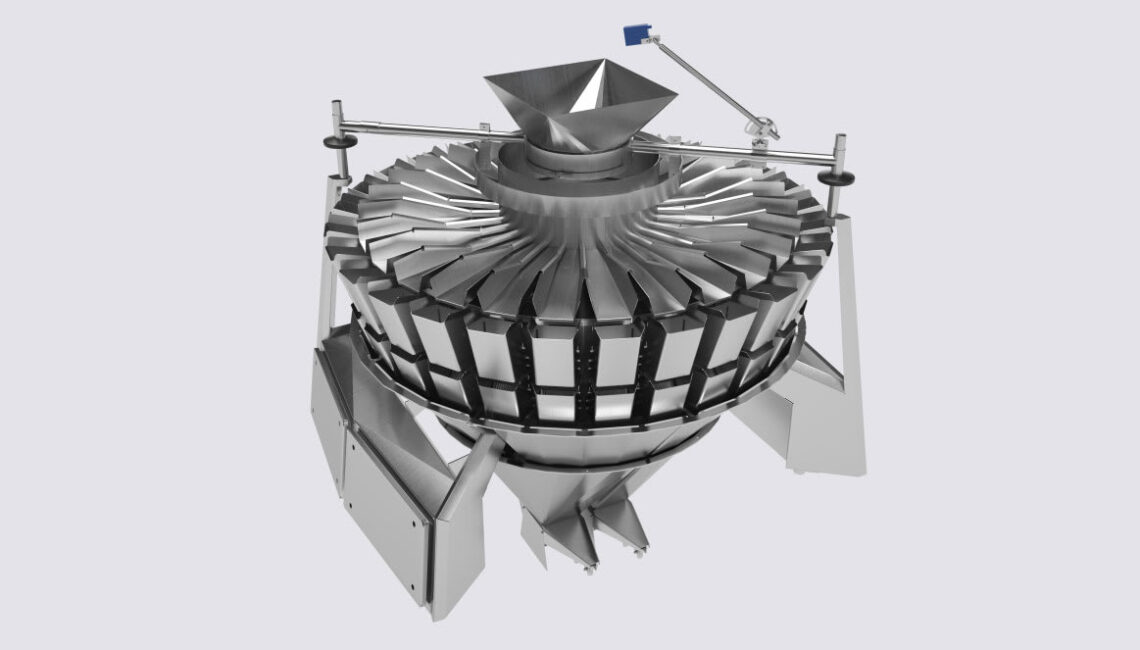

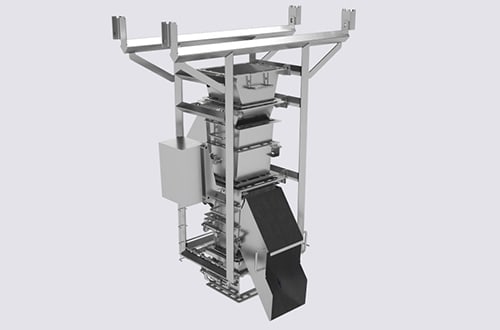

The solution is a complete line with three Multihead Weighers and various other equipment in order to automate the production. The line comes with a recipe control which secures full traceability of the products produced.

The Result:

The customer has automated the most labor intensive processes and reduced labor costs significantly. At the same time, give-away on the different products has been reduced significantly.

Benefits

- Reduction of labor

- Increased food safety

- Less give-away

- Full tracking of raw materials and finished products

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.