Who is the customer?

Our customer, Van Altena, is a Dutch spring roll producer. They specialize in making fresh spring rolls, with a primary focus on their 200-gram spring rolls.

What was their challenge?

As the demand for their spring rolls increased, it became impossible for their production to keep up with demand, working three shifts with a total of 20 employees: 12 for the day shift and 8 for the night shift. Most of the employees were focused on manually rolling and packing the spring rolls.

Meeting demands

A drastic change was necessary to meet their customers’ demands. Therefore, Van Altena turned to Cabinplant for a solution. The challenge was to provide a solution that could ensure higher capacity with fewer employees. The solution should consist of automated baking, filling, folding, and rolling of the spring rolls, thus reducing manual labor.

Automated solution

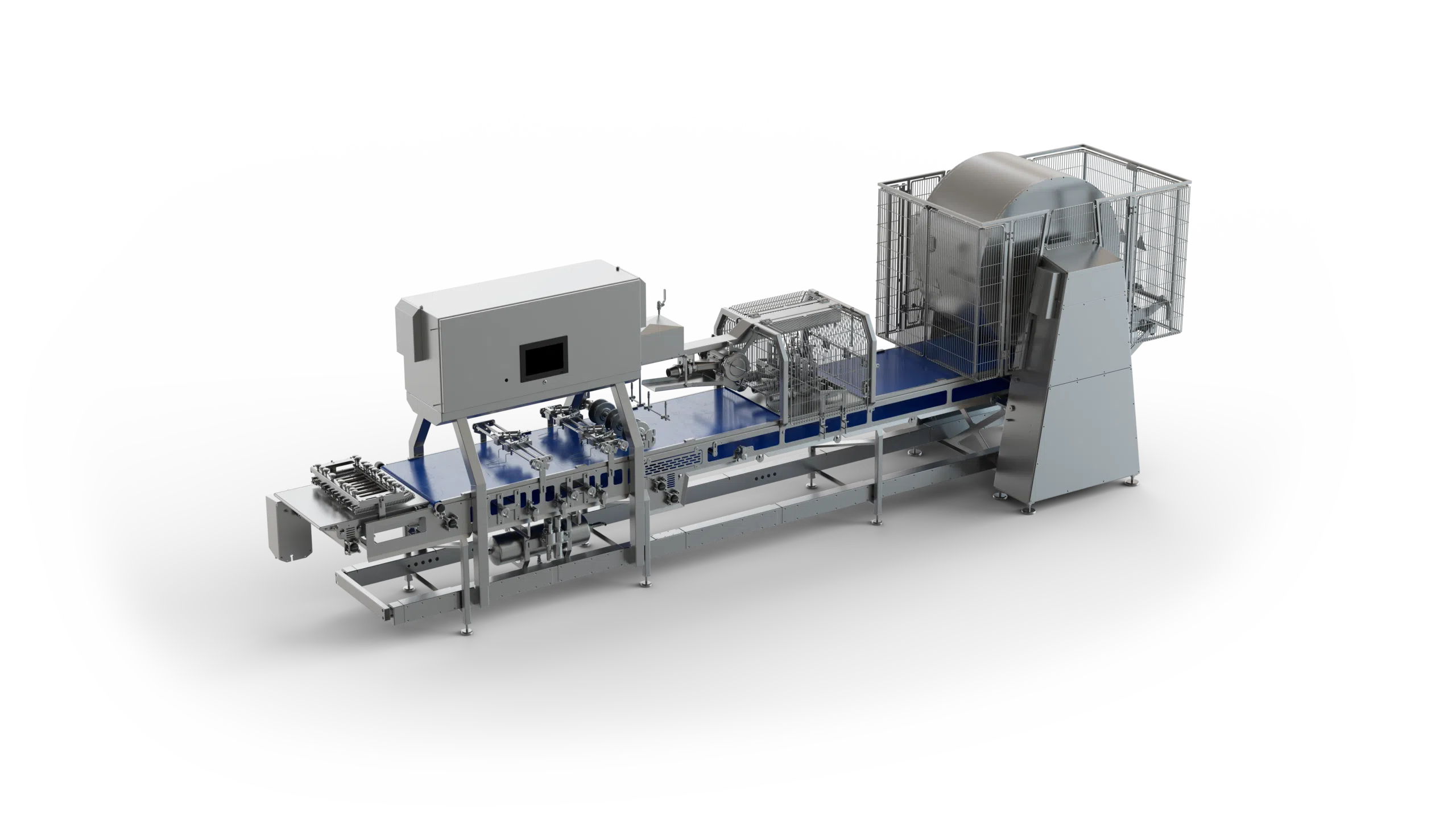

Cabinplant provided a solution in the form of our Spring Roll machine, which consists of automated dough application, baking, filling, folding, and rolling, all customized for Van Altena’s needs with respect to size, form, and weight.

As the Spring Roll machine has a compact design and is fully automated, an increase in capacity has enabled Van Altena to produce the same amount of spring rolls in less time. And therefore, they have been able to reduce production and labor costs. The solution features a double-lane machine equipped with a cast-iron drum, capable of producing up to 120 rolls per minute. Lastly, the solution offers different-sized roll formats, making the machine able to produce multiple sizes and types of spring rolls. This results in a need for only one machine for the entire production.

The result

With the Spring Roll machine, Van Altena has increased capacity while cutting labor and work hours. Van Altena has reduced production to only one shift and reduced labor from 20 to four people. As a result of the increased capacity, Van Altena has now reached multiple new retailers and is continuing to grow in the Netherlands as well as throughout the rest of Europe.

Customer testimonial

Get to know our customer, Van Altena, and our solution in more detail right here, where Albert Hak describes the process and Van Altena’s experience with Cabinplant.

"From the very beginning, I had the impression that Cabinplant was a trustworthy partner, and they have since lived up to that impression."

Benefits

- Low labor costs

- Increased efficiency

- Increased food safety

- Greater product homogeneity

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.