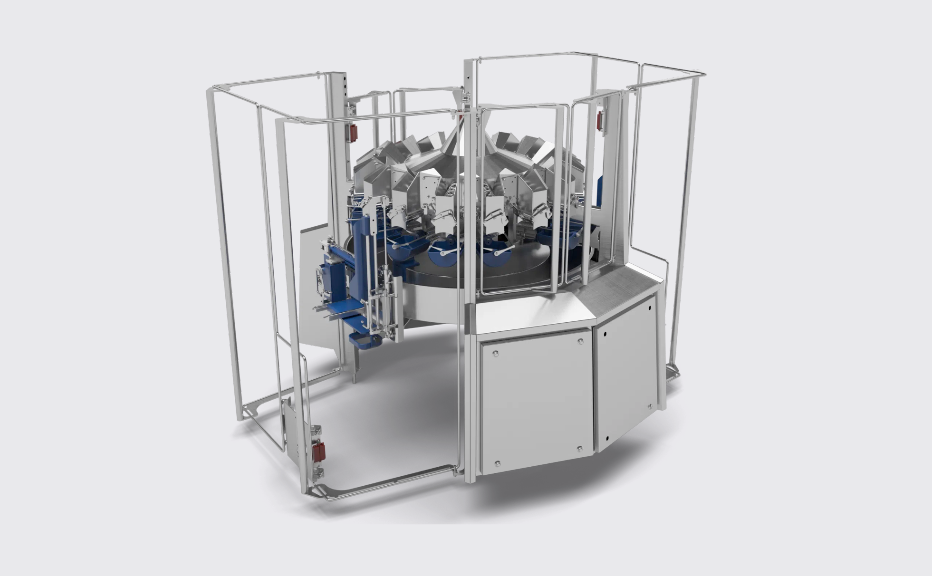

Multihead weigher machines are made for precise and efficient weighing

Optimize your production with our advanced multihead weigher machines, designed for precision, speed, and efficiency.

Multihead scale vs combination weigher?

A multihead weigher is also referred to as a multihead scale or a combination weigher. They are all the same thing using different terms. At Cabinplant, we offer versatile weighing solutions, that are designed to meet the diverse needs of a wide array of customer segments. With state-of-the-art equipment and tailored approaches, we address the unique challenges and opportunities present in food manufacturing.

Multihead weigher for extremely sticky products

Introducing the new Cabinplant MHW SF Extreme, one of the world’s most efficient and innovative weighing solutions for extremely sticky products.

- Cuts manual labor by up to 70%

- Easy to clean – cleaning time as low as 5-10 min.

- Handles products like tuna flakes, RTE pasta salads and similar products

With efficient and precise combinatorial weighing and the ability of handling of sticky products like mixed salads, coleslaw and tuna flakes, the MHW SF Extreme can easily process complex and demanding tasks.

This will automate your production and thereby cut manual handling by up to 70 % and increase food safety by bringing down human contamination risks.

"*" indicates required fields

Proven performance

The Cabinplant MHW SF Extreme is based on our Multihead Weighers with the screw feeding principle, which was invented by Cabinplant back in 2005. The screw feeding principle introduced the benefits of Multihead Weighing to processors of wet and sticky products and has made it possible for industries, in the meat & pultry, fish & seafood, fruit & vegetables and convenience food industries, to achieve higher weighing accuracy and to reduce give-away costs considerably.

Extremely small footprint

With its height of only 1,750 mm the Cabinplant MHW SF Extreme has one of the smallest footprint on the market for MHWs and can be placed in any production hall without having to cope with restrictions of building measurements in regards to height.

This makes MHW SF Extreme a natural choice for any large or small processing companies that want to automate the weighing of extremely sticky products.

Applications and benefits

- RTE salads

- RTE meals

- Tuna flakes

- Pulled meat products

- Cottage cheese

- other mixed and sticky products

- Cuts manual labor by up to 70 %

- Cleaning time/change-over time down to 5-10 minutes

- Ideal for automating even small production batches with frequent product shifts

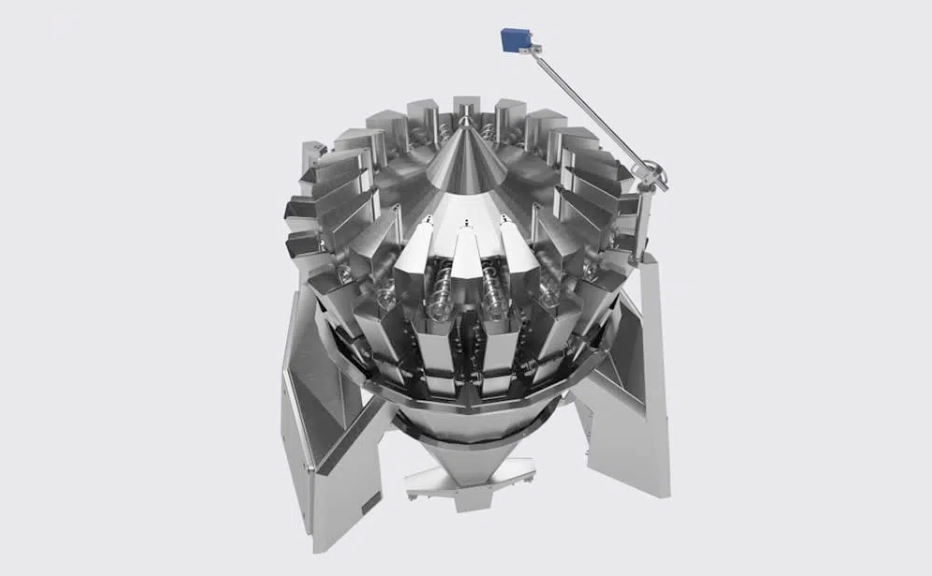

MHW with screw feeding

The Cabinplant MHW with screw feeding is a unique and patented solution that is perfect for handling sticky & wet products. Speed, flexibility, and precision are vital parameters when optimizing your cost of production.

The Cabinplant screw feeding principle has introduced the benefits of multihead weighing to processors of wet and sticky products. It has enabled industries in the fish & seafood, meat & poultry, fruit & vegetables, and convenience food industries to achieve higher weighing accuracy and considerably reduce giveaway costs. In addition, our customers have benefitted from a ROI of less than 18 months.

The Multihead Weigher gives you a well-proven and reliable weighing machine. Our Multihead Weighers with screw-feeding are available in a wide range of models, and we can, therefore, meet your specific demands and ensure optimal handling of your products.

"*" indicates required fields

Sensor gates increases accuracy

To obtain the highest possible number of combinations and achieve the highest degree of accuracy the weigher is only feeding one piece of product into each pan. The sensor gate ensures optimal feeding of each assembling pan, which is ideal for packing few-piece portions.

Functionality of the multihead weigher

The Multihead Weigher has several functionalities which help you increase accuracy and efficiency in the production.

The weigher always has continuous weighing, rotating cones on top and screw dosing time, that automatically adjusts as a function of partial portion weighing.

Furthermore rollers can be integrated between the individual channels when handling long products such as fresh fish, fillets or pasta.

Features & benefits

- Give-away close to zero

- Specially adapted product contact materials

- Minimum noise level

- Minimum maintenance

- Easy cleaning

- Continuous weighing

- Rotating cone on top

- Automatic screw dosing time

- Rollers can be integrated

- Hygienic design

Type of weighing:

- Single or multiple weighing

- Flow weighing

- Floating set-point weighing

- Single dynamic weighing (SDW)

- Dual dynamic weighing

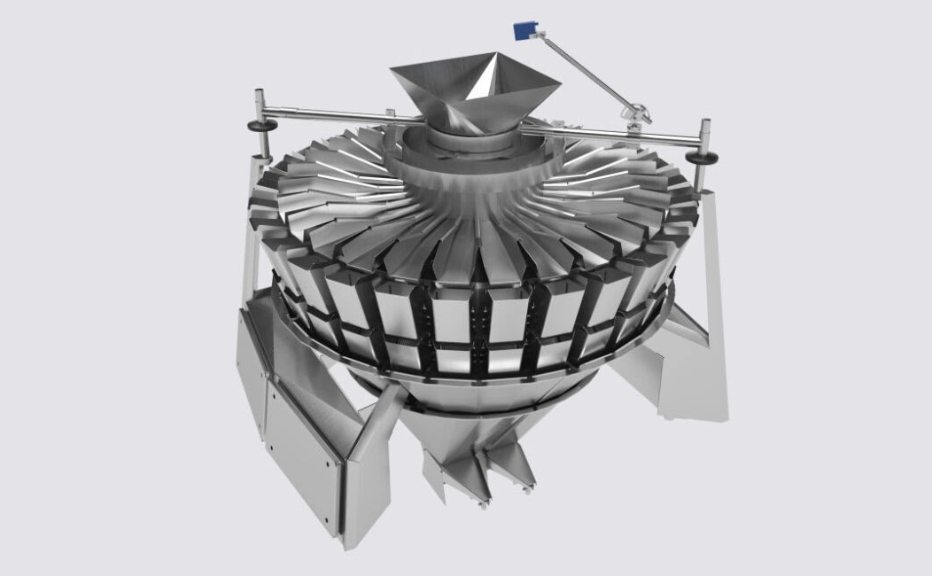

MHW with vibratory feeding

The Cabinplant MHW with vibratory feeding is designed to meet the increasing demands of precision and speed during the weighing process of complex products.

- Excellent weighing accuracy

- Minimum maintenance

- Hygiening designed

The traditional Multihead Weigher uses vibration to transfer and distribute products into the weighing pans. It is used for dry, frozen, and, to some extent, sticky products. The top cone conveys the product to the vibrator chutes using vibration. The vibrator chutes vibrate the product into the assembling pans using time and amplitude control.

"*" indicates required fields

Excellent weighing accuracy

With a Cabinplant Multihead Weigher you get a well-proven and reliable weighing machine. Our weighers with vibratory feeding are available in a wide range of models, and we can offer you a machine that will meet your specific demands and ensure optimal handling of your product.

Made for customer requirements

The MHW can be divided into four separate product zones and used to make exact mixes of the chosen products or work as an individual weighing unit for different products. With a Cabinplant Multihead Weigher, you can optimize your process and decrease your waist time, thus innovating your production.

The Multihead Weigher ranges from low-capacity 10-channel machines to high-capacity 32-channel machines, where the number of channels and weighting pan sizes are dictated by your needs.

Features & benefits

- No give-away when handling small negative tolerances

- Specially adapted product contact materials for handling sticky products

- Minimum noise level

- Minimum maintenance

- Easy cleaning

- Touch operator panel

- Continuous weighing

- Vibration cone on top

- Vibration dosing time automatically adjusted as a function of partial portion weighing

- Tailor-made design according to customer request

- Special surface for frozen and sticky products

Type of weighing:

- Single or multiple weighing

- Flow weighing

- Floating set-point weighing

- Multiple target weighing

- Mix weighing

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com