Thawing

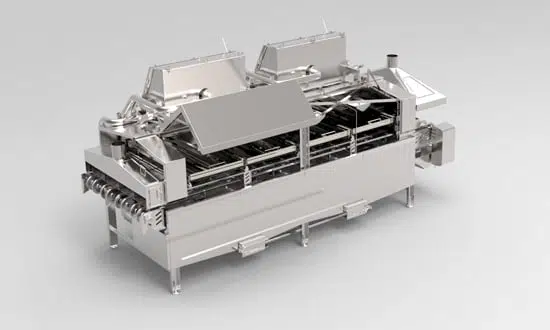

Belt Thawing - spray

Cabinplant provides a thawing unit using water spray for continuous thawing of block frozen products, such as cold water shrimp, herring, mackerel, etc.

Thawing time is short and water consumption is low compared to other solutions.

The unit operates with a first-in/first-out effect, the outermost product detaching and leaving the unit first, even though the core remains frozen.

Low water consumption

Short thawing time

Used for IQF or block frozen products

How it works

Thawing is with warm water (heated by steam), which is accumulated in the underlying vessel for recirculation.

From the vessel the water is pumped to a specially designed distribution tray, which secures a perfect and uniform water film over the blocks.

The blocks are placed manually in a vertical position in the infeed section of the thawing unit.

Automatic thawhing:

- Automatic thawing and separation of product during conveyance.

- Automatic collection on separate conveyor and discharge to accumulation conveyor.

- Automatic temperature control of thawing water.

Features & benefits

- Low water consumption

- Short thawing time

- Continuous thawing of block-frozen products

Facts & Use

- The thawing system is available in various sizes, depending on product type and required capacity.

- Block-frozen products: Whole fish, shellfish, fillets, meat

- IQF products: Shellfish.

What to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Contact a specialist

We have people all around the world who can help.